Past events

Exhibition Report of TECHNO-FRONTIER 2022

Event outline

TECHNO-FRONTIER is a technology exhibition that showcases the latest technologies and products in mechatronics, electronics, and specialized fields of those related. We exhibited sensor-compatible ink (infrared transmittable ink) that contributes to design improvement and cost reduction, printing technology that combines sensor-compatible ink with non-contact sensors, and electromagnetic wave shielding ink (newly developed product) that is flexible and can adhere to various materials.

- Period

- July 20 - July 22, 2022

- Venue

- Tokyo Big Site

- Official HP

- https://www.jma.or.jp/tf/index.html

List of Exhibits

1.Decorating technologies for non-contact switches applied in a variety of fields

1.What is a non-contact switch?

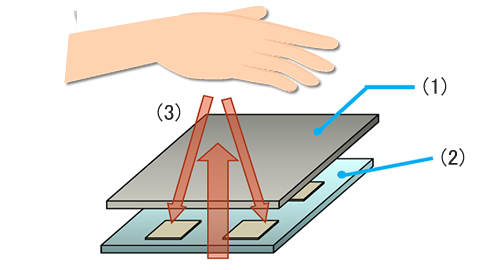

A non-contact switch can be turned on and off without touching it by a built-in infrared sensor detecting a hand held. By printing sensor inks on the infrared light emitting/receiving port, it is possible to create a design that does not make the user aware of the built-in sensor.

(1) Cover glass on which sensor ink was printed

(2) Sensor body (IC chip)

(3) Infrared rays sensor receives and emits

2.Sensor ink that expands the possibilities of non-contact switches

Sensor inks allow adjustment of the transmission wavelength and degree of transmission to match the characteristics of the sensor that the non-contact switch is incorporated with. In addition, sensor inks provide more freedom in decoration on non-contact switches, making it possible to apply them in a variety of fields.

| Direction of decoration | What you want to achieve | What sensor ink can support |

|---|---|---|

| Show | To stand out as non-contact switch for infectious disease control | Free design of switches without physical limitations |

| Hide | To detect only specific conditions without making people aware of the sensor. |

Allow seamless design to hide the sensor (Application of design improvement and security measures) Capable of detecting and responding to the specific situation without the user being aware of it. (Application of power saving to control power supply depending on the situation. Details to follow,) |

| Hide + Show | To hide the information when it’s not necessary and provide it when necessary | Combination with Dead front printing can provide “necessary information when needed”. (Shy Tech), (details to follow) |

3.Application to Non-contact buttons

Products that are touched by an unspecified number of people are beginning to be non-contact. By combining distance-measuring sensor and IR Transmittable ink, it is possible to apply this technology to non-contact buttons.

IR transmittable ink is ideal for those components which do not want to stand out sensor parts but do not want to degrade their functionalities.

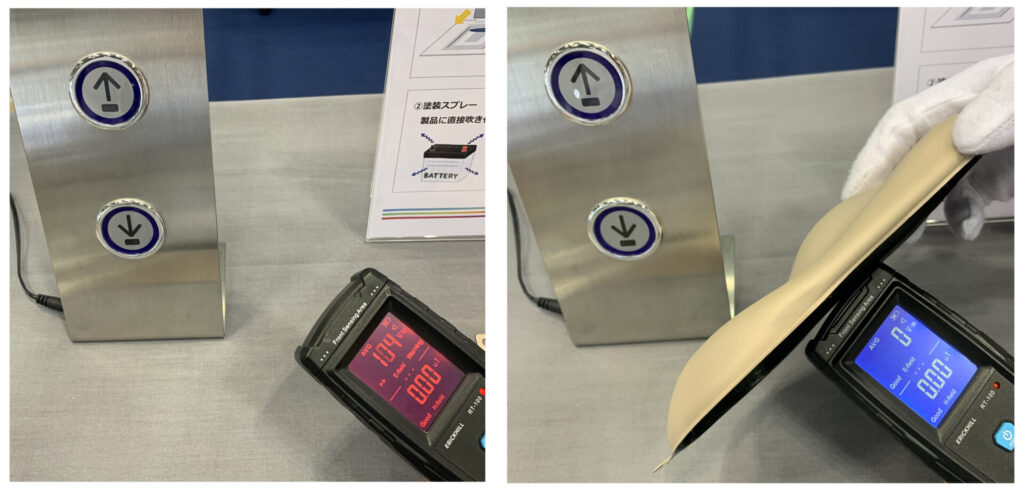

Below photos show that when the finger closes to the switch, the built-in sensor reacts and glows blue because infrared transmittable ink has been printed under the arrow marks.

Exhibition Cooperation: Elevisor Japan Inc., TOA Electronics, Inc.

2.Inks for electromagnetic wave shielding that contribute to product weight reduction

1.What is electromagnetic wave shielding ink?

Electromagnetic wave shielding ink is a kind of conductive ink which makes a conductive printed ink layer block (shield) intrusion or leakage of electromagnetic wave. Compared to other shielding materials such as metal foil, it is lighter, thinner, and has superior functionality such as high moisture resistance.

The following photos show that the printed matter with electromagnetic wave shielding ink (film coated with spray) shields electromagnetic waves (in this example, radiation electric field was measured) emitted from the non-contact switch demo machine. The radiated electric field is shielded from measurement value in normal time (118 V/m) (left photo) to immeasurable value (0 V/m) (right photo).

We introduced the example in the 13th Automotive World that the screen printing film shields electromagnetic waves.

2.Characteristics of electromagnetic wave shielding ink

Electromagnetic shielding ink has four characteristics.

- It is possible to make products lighter and thinner by combining with resin materials

- Adhere to a wide range of materials

- Pattern print, only necessary part, is possible.

- With only one type of ink can shield a wide range of frequencies (from 0.1MHz to 8.5GHz).

Unlike other electromagnetic shielding materials, this product has both electromagnetic shielding effect and screen printing merits.

3.Performance of electromagnetic wave shielding ink

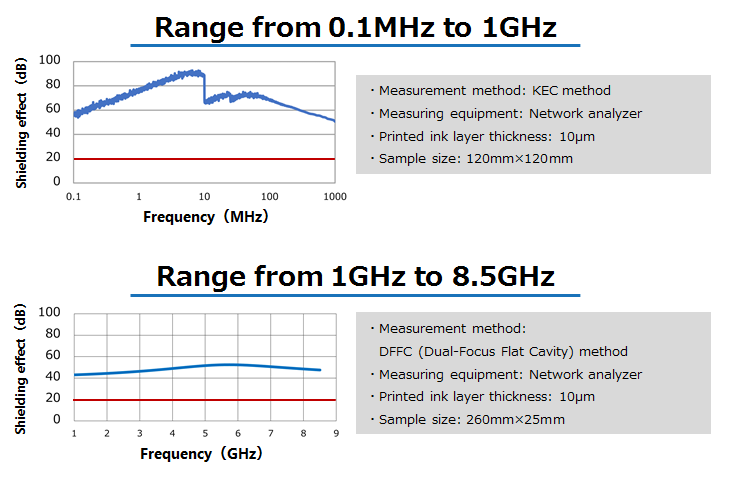

Shielding effect of electromagnetic wave shielding ink can be adjusted depending on the resistance value and the printing conditions of ink. The following are the results that shielding effect in each frequency range was measured.

4. How to use electromagnetic wave shielding ink

(1) Screen printing: It is possible to print partially with the shape that needs a shielding function.

(2) Spray Painting: It is possible to add electromagnetic shielding function by spraying ink directly on the product.

5.Printing example of electromagnetic wave shielding inks

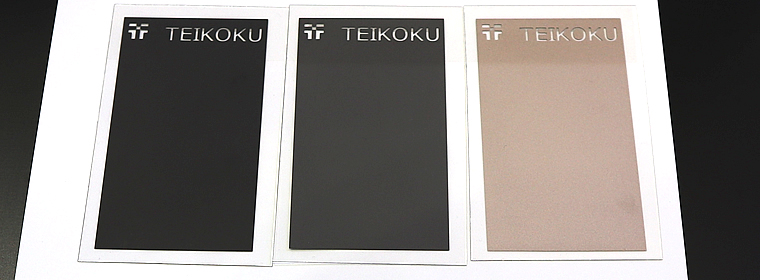

The followings are printing samples of MRX-HF Conductive Black, Gray, and Brown ink. Electromagnetic wave shielding inks can do both shielding electromagnetic wave and decorating in a single printing process. In case of decorating other than standard colors, it is possible to express designs freely by overprint with regular inks.

・Printing example of MRX-HF Conductive Black, Gray, and Brown ink.

Printing conditions:

Black・Gray T-250 Mesh, Z-004 Solvent 5%, 210 Catalyst 5%, 80°C for 30 min

Brown T-250 Mesh, SM-800 Additive 10%, 210 Catalyst 5%, 80°C for 30 min

・Example of spray painting of MRX-HF Conductive Brown

Spray painting conditions: Z-701 Solvent 100%, 210 Catalyst 5%, 80℃ for 30 min

Please feel free to contact us about the inks, methods, and trial products we have introduced.