Plastic plates with improved scratch resistance

Hard Coat

Transparent plastics are rather light, not easily breakable, and easy to forming compared with glasses, but easy to get scratch and scars.

Recently there were introduced many types of hard-coated plastics which are not easily get scratches.

We will explain the differences of the hard-coated plastics and our inks for these plastics.

1. The surface of the hard-coated plastics.

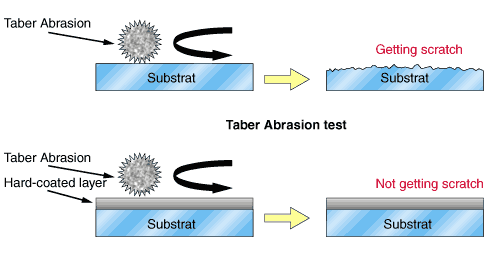

he surface of the hard-coated plastics has an extremely good Taber Abrasion resistance.

2. Required quality of hard-coated layer.

a) Hard surface and hard to get scratch. Taber abrasion test delta ΔHt < 10% (ASTM D1044 CS-10F 500g)

b) Excellent transparency. Transparency > 90%

c) Weather resistance will be enhanced by using UV absorbing materials.

d) Good resistance to chemicals.

3. Applications of hard-coated plastics.

Optical lenses

Electric appliances panels

Car parts

Covering of Electric illuminations

Architectural members

4. Grades and special features of hard –coat

4.1. Hard-coating chemicals

| Chemicals |

chemical composition

|

hardness | special features | drawbacks |

|---|---|---|---|---|

| Organic | Melamine Urethane resin Acrylic resin |

rather hard | easy to handle re-coating easy |

less hardness less durability |

| Multifunctional UV acrylic resin Weather resistance may be |

Hard | Re-coat possible Easy to handle harmed by residuals. |

Weather resistance may be harmed by residuals. | |

| Silicone | Silane | Hardest | Good hardness and Durability. |

Poor re-coating ability |

| Inorganic | Metal oxides | Hard | Vacuum deposition | Adhesion to plastics is doubtfull. |

4.2. Sheet substrate

As substrates for hard coating, Acrylic resin and Polycarbonate are generally used.

Acrylic hard-coated resin are used mainly as flat sheets.

PC hard-coated resin can be used as curved sheets.

5. Our screen ink for hard-coated plastics.

We developed “MAB Ink” for printing on Organic hard-coated plastics, such as Melamine, Urethane and UV hard-coated resins.

Special Features of MAB Ink

Two-pot solvent ink

Good adhesion to organic hard-coated resin surface.

Flexible and durable, post forming suitable

Good resistances

- Related inks