Coexistence of metallic design and non-conductivity

Introduction of non-conductive Metallic ink

A news to those in charge of development of electronic equipment products and hope for new design.

We will introduce non-conductive Metallic ink which supports metallic design and non-conductivity at the same time.

1. Coexistence of metallic design and non-conductivity

1. Resolve problem of current Metallic inks

Metallic ink provides excellent design such as producing high-grade sense by unique gloss color.

There was limitation in its use for electrical equipments, with fear of electrical circuit short or radio disturbance caused by energization of printed ink layer due to conductive Metallic powder used.

Non-conductive Metallic ink made it possible to use metallic design for electrical equipments such as smartphones, etc. by solving this conductivity problem.

2. Electrical resistance value of non-conductive Metallic ink

Electrical resistance value of normal Metallic inks is about 104-5Ω.

On the other hand, electrical resistance of non-conductive Metallic ink is over 109Ω which is more than 10,000 times as much as normal. This high resistance value realizes metallic design for electrical equipments.

GLS-HF ink series is applicable ink for non-conductive Metallic.

|

Ink

|

Normal Metallic | Non-conductive Metallic |

|---|---|---|

| Electrical resistance | About 104-5Ω | Over 109Ω |

2. Introduction of examples for non-conductive Metallic inks

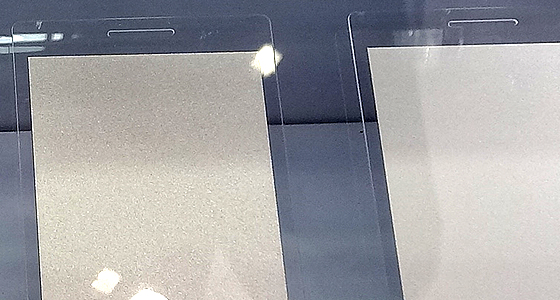

1. Gloss variation

Non-conductive Metallic ink provides 3 gloss variations by changing grain sizes (small, medium, and large).

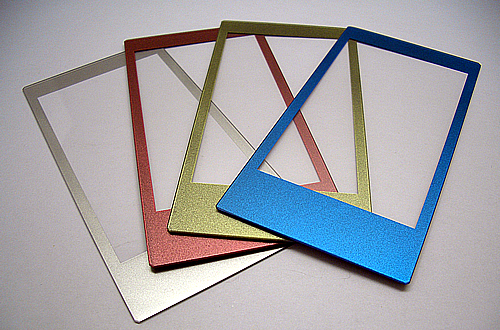

2. Color variation

Non-conductive Metallic ink also provides diverse color variation. The following picture is an example of providing smartphone window frame with various colors.

- Related event information

- Related inks