Introduction of new decoration of PP resin product by using Film Insert Molding (FIM)

Introduction of new decoration of PP resin products.

Good news to those who are in charge of developing PP resin products.

We will introduce Film Insert Molding (FIM) using PP resin for both decorative sheet and molding resin.

1. Realize Film Insert Molding (FIM) by using PP resin sheet and molded object of PP resin.

1. Problem and solution of existing decorating method for PP resin product

PP resin (Polypropylene), providing low specific gravity, excellent workability, and high strength compared to all the resins, is used for various industrial products. In case of using PP resin for industrial products, vinyl chloride sticker is often used for surface decoration.

Decoration with vinyl chloride sticker was not the best decorating method due to difficulty in decorating concave portion and necessity of peeling off at the time of recycling. However, it was difficult to apply other decorating method such as Film Insert Molding (FIM), etc. in terms of technical issues.

In such a situation, new development of IMB-HF007 PP Binder firmly adhering PP decorative film and PP resin enabled Film Insert Molding (FIM) for molded product of PP resin using molding ink, INQ-HF.

As a result, we can use PP resin positively for the materials which require designing and recycling properties in addition to weight saving, such as motorcycle and automobile parts and home appliances.

2. Realization of Film Insert Molding (FIM) by using PP resin sheet and molded object of PP resin.

Film Insert Molding (FIM) process using PP resin sheet and molded object of PP resin is as follows.

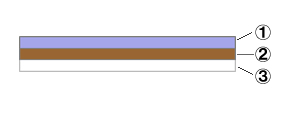

1) Screen printing |

(1)Binder (IMB-HF007) and (2)Decorative ink (INQ-HF) on (3)Decorative film (PP resin) |

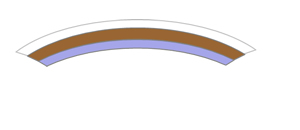

2) Forming |

Forming decorative film printed. Decorative film side as frontside surface and printed layer as backside surface. |

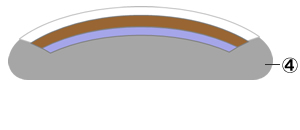

3) Injection |

Injection by pouring (4)Molding resin (PP resin) into decorative film formed. |

3. Comparison of existing vinyl chloride sticker and Film Insert Molding (FIM)

Most of the problems in decoration by using vinyl chloride sticker have been improved by Film Insert Molding (FIM) as indicated below.

| Item | Vinyl chloride | Film Insert Molding (FIM) |

|---|---|---|

| Design | Design for concave portion is difficult. | Design for concave portion is possible. |

| Looks like sticker. | Looks like printing. | |

| Printing film on the surface side. Design is less flexible. | Printing film on the back side. Design is more flexible. | |

| Process | Adhesion technique is required. | Adhesion technique is not required. |

| Recycling | Separation process is required as quality of material differs between vinyl chloride and PP resin. | Separation process is not required as material of decorative film and molded object is the same, PP resin. |

2. Introduction of the examples

1. Examples of Film Insert Molding (FIM) using PP resin film and molded object of PP resin

This photo is an example of applying beautiful wood-grain PP resin film to the molded object of PP resin.

This is an example of integral molding of more colorfully decorated PP resin film with PP resin plate.

- Related technology information

- Related event information

- Related inks