Past events

Exhibition Report of Converting Technology Exhibition 2018

Event outline

In "Exhibition Report of Converting Technology Exhibition 2018", we exhibited at "3Decotech Expo 2018" having the theme of technology and materials which provide design property and functionality of products.

This time, we introduced our latest printing and ink technology by focusing on High Definition Ink System (High Quality and High Definition Screen Printing Ink).

- Period

- April 05 - 07, 2018

- Venue

- Tokyo Big Sight

- Official HP

- http://convertechexpo.com/en/index.html

List of Exhibits

- 1. Introduction of 7 benefits of High Definition Ink System

- 2. Proposal of reducing production process with High Definition Ink

- 3. Proposal of enhancing design quality with Film Insert Molding (FIM/IMD)

- 4. Introduction of ink for sensor that assists self-driving and AI

- 5. Proposal to assist the improvement of products usability and safety

- 6. Proposal of both reduction of environmental burden and cost reduction by substitution for metal plating

1. Introduction of 7 benefits of High Definition Ink System

1. Fine Printability

High Definition Ink system enables printing 100µm fine line like a hair with 100µm to 116µm accuracy. It also stably provides 100µm dot diameter of gradation. As a result, it can print expressions and designs beautifully with high resolution that was impossible in conventional screen printing.

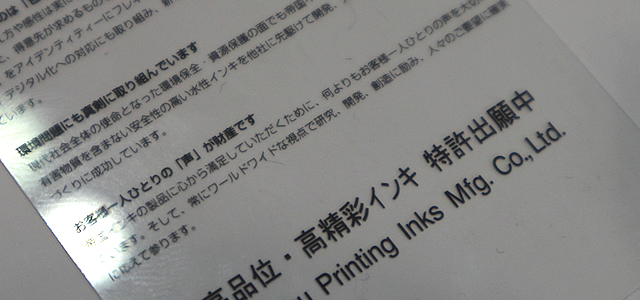

- Example of printing accurately on Kanji (Chinese character) consisting of many number of strokes (line width 50µm) without bleeding.

-

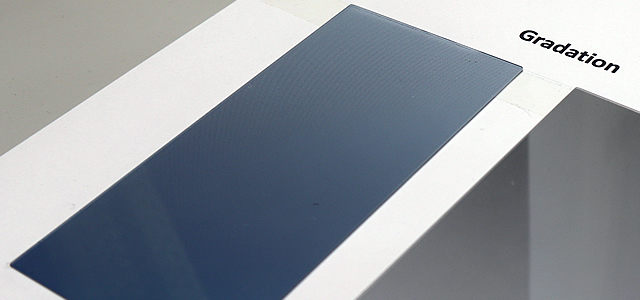

- Example of expression of beautiful gradation with 100µm level of fine dot pattern

-

2. Printability of solid printing (simultaneous printing of solid printing and fine lines)

Conventional ink requires to change printing conditions and stencils because printing condition varies depending on solid printing, gradation and fine lines and that causes cost increase. However, High Definition Ink system is able to print solid printing, gradation and fine lines at the same time. Thanks to that, we can achieve both improvement of decorativeness and cost reduction.

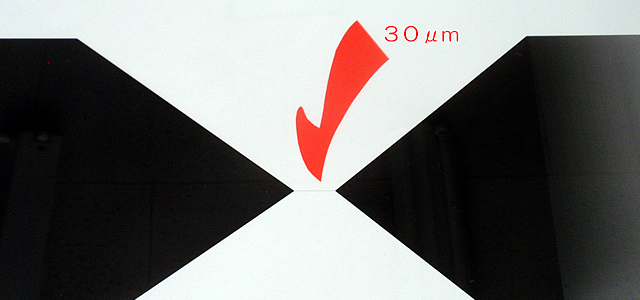

- Example of simultaneous printing of solid printing with fine lines (30µm) and gradation.

-

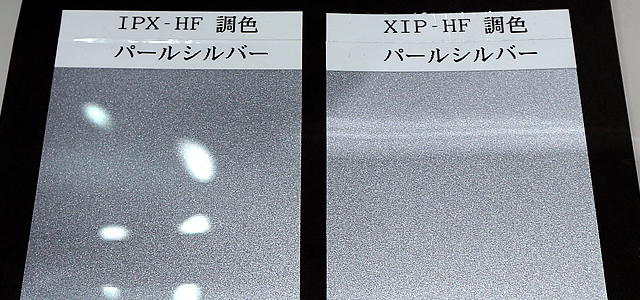

High Definition Ink system also shows its strength in solid printing. It creates beautiful solid printing without unevenness on functional ink such as metallic, pearl, mat and AG (anti-glare), which easily make unevenness occur in conventional ink.

- Example of printing of Pearl Silver (High Definition Ink (right side photo))

-

3. Countermeasure for saw edge (concavo-convex)

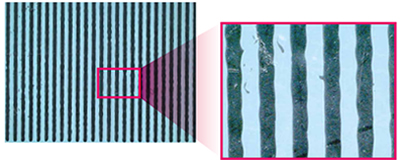

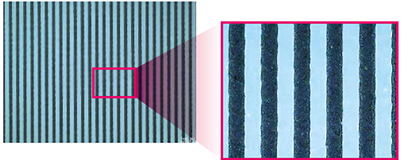

It is possible to print beautiful straight line and true circle without concavo-convex and beautiful outline letter with less than 10µm saw edge.

- In conventional ink (left side photo), jag occurs at boarder line. High Definition ink (right side photo) can create a beautiful printing boarder line.

-

4. Continuous Printability

Continuous Printability achieves both improvement of production efficiency and reduction of defective rate. It enables both printing fine lines with 100µm to 116µm of line and space, and 1500 sheets of continuous printing

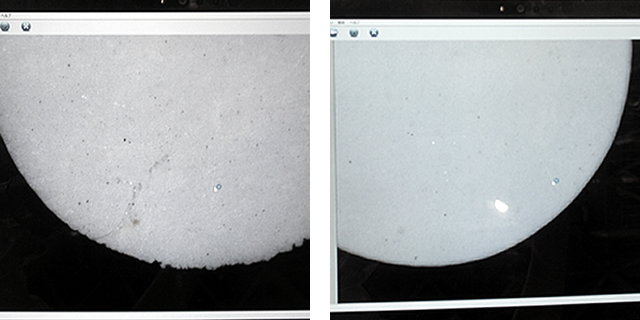

- In conventional Ink (left side photo)(up), ink spatter occurred at printing 300th sheets. In High Definition Ink (right side photo)(down), stable finish is possible even after 1500 sheets of continuous printing.

-

5. High Speed Printability

It enables both fine printing with 100µm to 116µm of line and space and high speed printing at 800 to 1500 sheets/hour with cylinder press.

- Example of fine printing printed by high speed

-

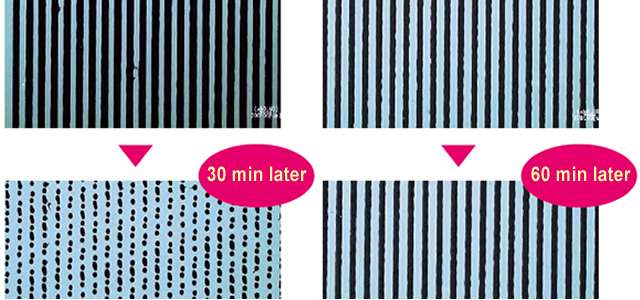

6. Re-printability

Re-printing is possible even if ink is left for 1 hour on the stencil. Working property such as reducing time of interruption of printing operation improves drastically.

- Leaving conventional ink (left side photo) for 30 minutes on stencil. Leaving High Definition Ink (right side photo) for 60 minutes on stencil.

-

7. Reduction of frequency and time of cleaning stencil

Conventional ink requires stencil cleaning about every 20 minutes depending on the printing contents. However, High Definition Ink system requires stencil cleaning only once every 90 minutes even printing fine design.

-

Stable printing reduces the number of cleaning stencil to one fifth !

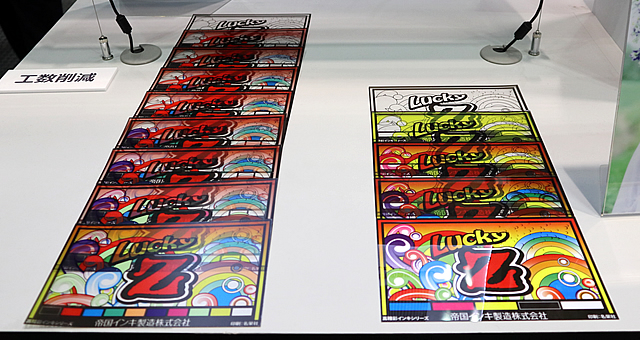

2. Proposal of reducing production process with High Definition Ink

1.Drastically reducing cost of platemaking and operation. Reduce 10 platemaking and 10 processes to 5 platemaking and 5 processes:

In general, when color illustrations and photographs are printed by screen printing, they are printed after color was separated and laid over according to hue of image. Therefore, the more color numbers make number of stencils and processes increase and that causes cost increase.

However, as High Definition Ink for color separation can reproduce high definition image even 4 colors, it can reduce number of stencils and processes and it can print colored illustration images and photo images at low cost.

Application:

Colored decoration products, high definition image printing

- Conventional ink (left side photo) requires 10 platemaking 10 processes. High Definition Ink (right side photo) succeeds in 5 platemaking 5 processes.

-

3. Proposal of enhancing design quality with Film Insert Molding (FIM/IMD)

1.Film insert molding (FIM/IMD)

Film Insert Molding (FIM) is also called In-Mold Decoration (IMD). The method that screen printed film is inserted into a mold to decorate molded products by integrated molding.

FIM/IMD can decorate with multiple color, fine lines and gradation which are difficult in painting. It is also excellent for durability and productivity (reduction of number of components and dealing with small lot).

- Example of decoration of molded product combined with gradation and fine lines that cannot be created in painting.

-

2.Decoration of PP resin by FIM/IMD

PP resin is applied to various industrial products as it has low specific gravity and high strength. FIM/IMD can decorate on PP resin molded products which were difficult in the past.

Product features:

1) Realize weight saving and strengthening.

2) Excellent decoration and efficiency than PP resin and vinyl chloride sticker.

3) Easy to recycle as it is integrated molded decoration that PP resin and PP film are merged together.

Application:

Two and four-wheeled automobile components, home appliances, mobile phones, and building materials

- FIM/IMD process: (1) screen printing (2) forming (3) injection

-

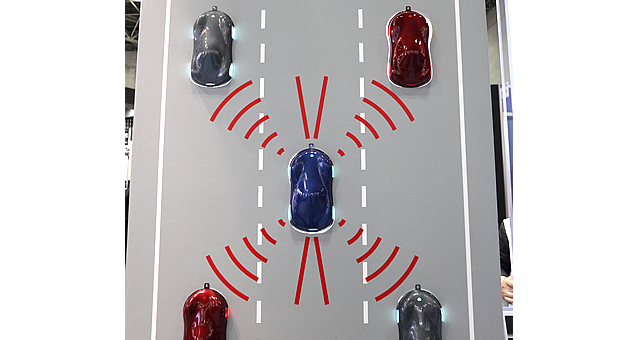

4. Introduction of ink for sensor that assists self-driving and AI

1.Accuracy improvement of sensor device with ink for sensor

Accuracy improvement of sensing function is essential for self-driving of vehicle and automation of various products by AI. Ink for sensor helps various types of sensors with high definition and preventing malfunctioning.

Product features:

1) Possible to select and limit wavelength to be transmitted based on the type of sensor.

(Prevent intrusion of unintended wavelength light and reduce sensor malfunction.)

2) Excellent smoothness (leveling) of printed ink layer prevents malfunctioning due to diffuse reflection.

3) Possible to conceal the sensor receiver by reflecting visual ray.

(Achieve both function and decorativeness, and can be applied to security purpose.)

Application:

Sensor for self-driving, sensor for automation of various devices, sensor for automation of factory and facilities, and sensor for security purpose (entrance control and personal authentication, etc.)

- Example of self-driving utilizing sensor function

-

- Example of fingerprint authentication device with high quality design combining fingerprint authentication component and housing color

-

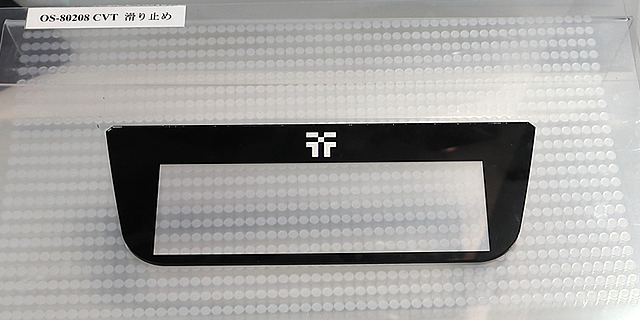

5. Proposal to assist the improvement of products usability and safety

1.Improve products usability and safety by providing anti-slip function

Providing anti-slip function on home appliances and housing of electric devices can enhance grip force during use of the product, improve usability of product and prevent a falling accident.

Application:

Home appliances, and smartphones

- Example of clear with anti-slip function printed by dots.

The display item (black window frame printing) has kept without slipping off. -

6. Proposal of both reduction of environmental burden and cost reduction by substitution for metal plating

1.Mirror ink realizes very high gloss of metal plating level (mirror effect ink)

As substitution for metal plating, mirror ink has advantage in cost and it can be applied to home appliances, mobile phones, automobiles, etc. Moreover, it can also be applied to optical instrument and component of electric device by utilizing light reflectivity of mirror surface.

Product Features:

1) Excellent mirror surface formation: Enables making printed ink layer of clear mirror surface without unevenness.

2) Excellent printability: Excellent printability and suitable for outline and convex characters.

3) Environmentally friendly: Mirror ink does not contain hazardous substance and vinyl chloride resin.

(Comparing to metal plating, mirror ink is more environmental safety and can reduce cost for environmental measures.)

4) Application of optical function: Light reflectivity of mirror surface can be applied to components of optical and electronic equipment.

Application:

Home appliances, mobile phones, automobiles, optical components, and electronic components

- Example of exhibition material reflected on the mirror surface

-

- Related technical information

-

- Introduction of High-Definition Ink (high-quality, high-definition screen ink)

- High Definition Ink System for Molding

- Introduction of 7 benefits

- Introduction of High Quality and High Definition Screen Printing Ink

- Introduction of new decoration of PP resin products.

- Technology lecture for FIM/IMD 1st session: Explanation of the merit and 3 process.

- Technology lecture for FIM/IMD 2nd session: Explanation of the screen printing process.

- Technology lecture for FIM/IMD 3rd session: Explanation of the Forming Process.

- Technology lecture for FIM/IMD Final session: Explanation of the Injection Process

- Introduction of IRX-HF ink

- Introduction of GLS-HF ink(2)

- Introduction of IR transmittable ink (IR Transmitting Ink) and concealed printing

- MIR-51000 Mirror Silver

- Mirror Ink (Mirror effect ink), substituting metal plating

- Introduction of MIX-HF ink(3)

- Introduction of MIX-HF(1)

- Related event information

Please feel free to contact us about the inks, methods, and trial products we have introduced.