Past events

Exhibition Report of CEATEC JAPAN 2016

Event outline

CEATEC JAPAN 2016 is the exhibition event that brings together the technologies toward the coming age of data-driven type or information utilization type society.

In this exhibition, we introduced our latest printing and ink technology by mainly focusing on High Definition Ink (High Quality and High Definition Screen Ink) we announced in July 2016.

1. Printed and molded article using High Definition Ink System

2. SELF-RESTORING CLEAR, CHEMICAL RESISTANCE CLEAR, and lighting decoration system, etc.

In this exhibition, we introduced our latest printing and ink technology.

- Period

- October 04 - 07,2016

- Venue

- Makuhari Messe

- Official HP

- http://www.ceatec.com/

List of Exhibits

- 1. Introduction of excellent decoration property in High Definition Ink (High Quality and High Definition Ink)

- 2. Introduction of excellent printing quality of High Definition Ink

- 3. Introduction of High Definition Ink contributing to cost reduction of electrical parts

- 4. Introduction of SELF-RESTORING CLEAR Ink

- 5. Introduction of Chemical Resistance Clear

- 6. Introduction of lighting decoration system applying reflecting light and transmittance function

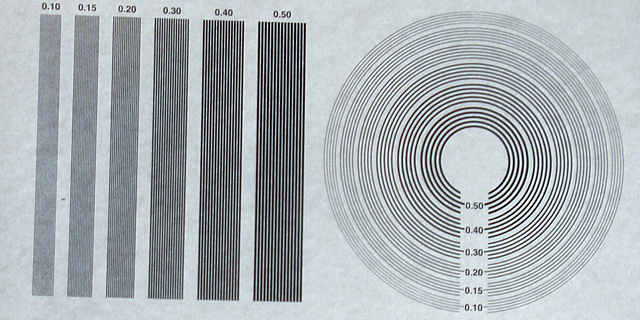

1. Introduction of excellent decoration property in High Definition Ink (High Quality and High Definition Ink)

1.Realization of simultaneous printing of beautiful solid print, very fine line, and high resolution gradation

In conventional screen printing, it was difficult to realize 100µm(=0.1mm)fine line printing and gradation expression of 130-lpi (line per inch). However, High Definition Ink not only realizes those fine line printing by single item, but also simultaneous printing with solid pattern with one stencil.

Application examples:

Automotive interior, home appliances, and smartphones

- The following photo is gradation sheet with very high resolution printed by 175-lpi and its molded object.

-

- The following is an example of molded article printing fine pattern (0.15mm deformation spin pattern).

-

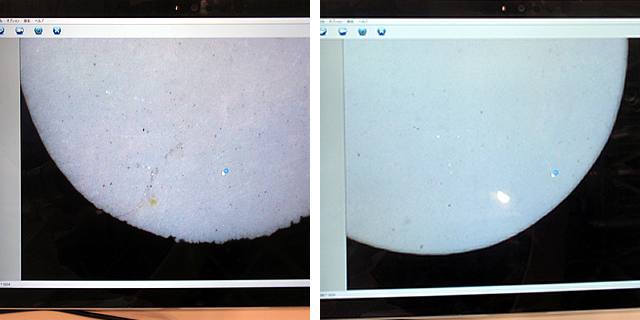

2. Introduction of excellent printing quality of High Definition Ink

1.Excellent printing quality realizing very smooth printed boundary without concavo-convex

In conventional screen printing, there was problem of serrated concavo-convex occurred in printed boundary part. High Definition Ink solved this problem and realized smooth printed boundary which defies conventional wisdom of the industry.

Application examples:

Automotive interior, home appliances, and smartphones

- We printed black window frame and true circle outline of 1mm diameter on the glass and took microscope photograph.

-

- In conventional ink (left side photo), jag occurs in printed boundary. High Definition Ink (right side photo) realizes beautiful printed boundary.

-

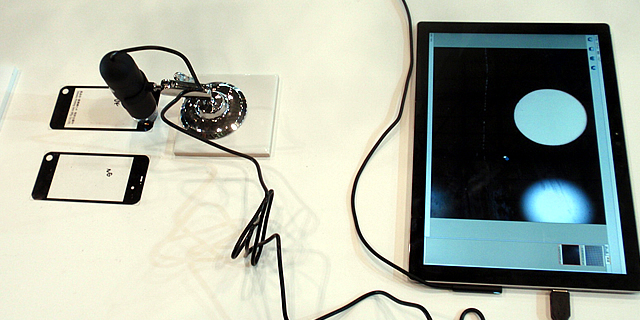

3. Introduction of High Definition Ink contributing to cost reduction of electrical parts

1.Fine printability applicable for printed electronics field

High Definition Ink is also small-scale and inexpensive screen printing technology substituting for technique requiring large investment such as photoresist, etc.

High Definition Ink enables stable printing of very fine line below 100µm depending on conditions. If you consider cost reduction in electronics-related business, please feel free to contact and consult us.

Application examples:

Electronic device

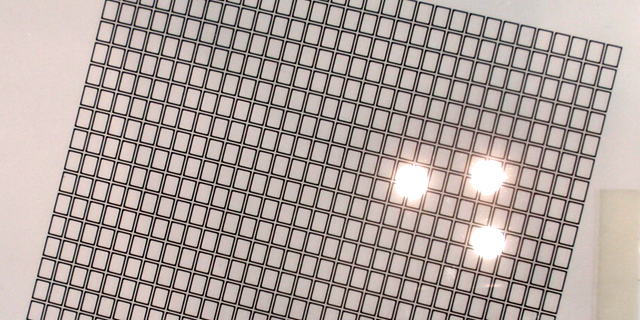

- Example of 100µm level fine printing without bleed or defect. (Enables outline printing also.)

-

- Printing example of well-proportioned lattice pattern without distortion or unevenness.

-

4. Introduction of SELF-RESTORING CLEAR Ink

1.Repairing damage during use and realizing brand-new product-like beauty

This Self-Restoring Clear Ink is Clear for surface protection providing self-restoring function on printed ink layer which can obscure surface scratch and abrasion damage occurring at the time of using product and maintain brand-new-like conditions for long time.

High elastic force of printed ink layer is applicable to anti-slip function.

Application examples:

Automotive interior, home appliances, and smartphones

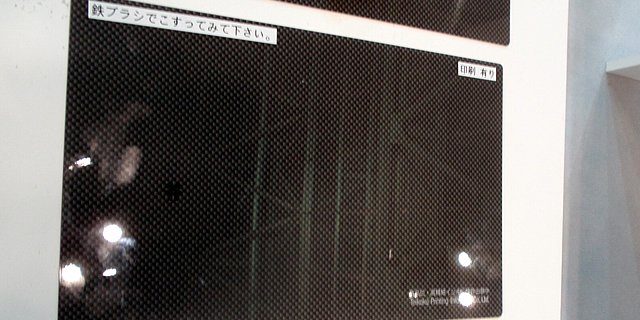

- In surface without printing of Self-Restoring Clear, scratch caused by wire brush and therefore diffuse reflection occurred.

-

- Brand-new product like gloss is maintained on the printed surface of Self-Restoring Clear.

-

5. Introduction of Chemical Resistance Clear

1.Realizing chemical resistance respond to high resistance standard for automotive interior:

This Clear is applicable to high chemical resistance required for automotive interior.The ink provides strong resistance to chemicals with strong corrosive action such as sunscreen, etc. Both design property and beauty substantivity are realized by using this Clear for parts touched by hands which deteriorates over time.

Application examples:

Automotive interior, home appliances, and smartphones、Touch Panel

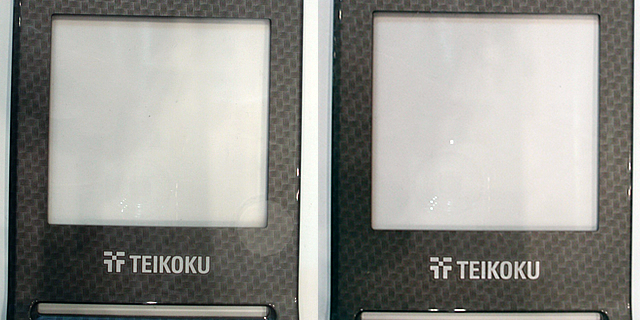

- In conventional Clear (left side photo), corrosion caused by sunscreen (Neutrogena) is recognized.

In chemical resistance Clear (right side photo), beautiful gloss is maintained without corrosion. -

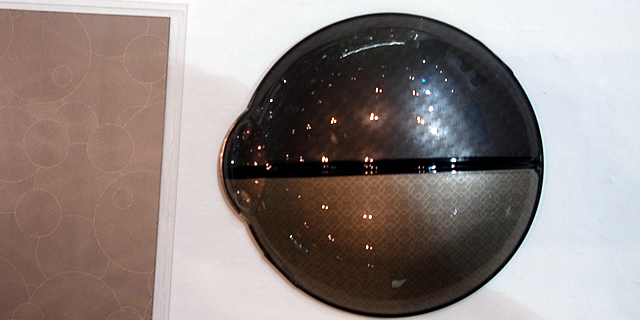

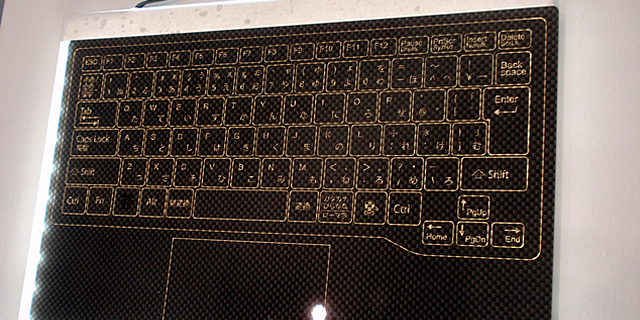

6. Introduction of lighting decoration system applying reflecting light and transmittance function

1.Realization of new expression by controlling reflecting light interference and transmitted light wavelength:

Control and interference of reflecting light enables unique expression such as rainbow color, etc. This technology can be applied to security field.

IR transmittable Ink also enables controlling wavelength of transmitted light from infrared light to visible light ray. Dynamic design such as design display at the time of back light irradiation only by devising wavelength of transmitted light.

Application examples:

Automotive meter, home appliance indicator

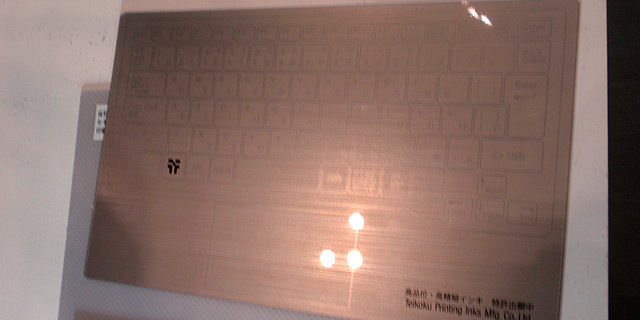

- Example of expressing unique gloss by lighting from the front side

-

- Example of mechanism that keyboard emerges at the time of lighting back light

-

- Related technical information

-

- Introduction of 7 benefits

- Introduction of High Quality and High Definition Screen Printing Ink

- Introduction of High-Definition Ink (high-quality, high-definition screen ink)

- Introduction of FLG-HF G05

- Introduction of IRX-HF ink

- Introduction of GLS-HF ink(2)

- Introduction of IR transmittable ink (IR Transmitting Ink) and concealed printing

Please feel free to contact us about the inks, methods, and trial products we have introduced.