Combine compatibility with high performance sensors and designability

Ink for sensor realizes even higher performance

Good news those who are developing smartphones and automobiles and considering using high performance sensors.

Ink for sensor became more functional and more accurate.

Ink for sensor combines compatibility with high performance sensor such as enhancement of adjustment function of transmitted light and transparency improvement by reducing haze value and designability improvement.

1. What is ink for sensor ?

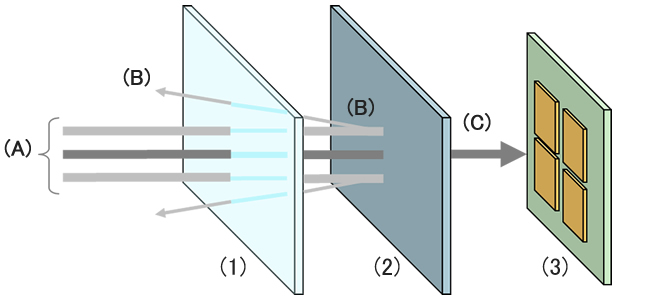

Ink for sensor transmits IR and blocks visible light and UV rays.

Ink for sensor, also called IR (infrared ray) transmittable ink, is a decorative ink that blocks visible light and UV rays that cause sensor malfunction and transmits only IR that should be detected. This ink enables us to improve sensor accuracy and also decorate the light receiving port.

(A) IR to be detected and visible light and UV rays causing malfunctions,

(B)Visible light and UV rays blocked (absorbed or reflected) by ink for sensor, (C)Transmitted IR

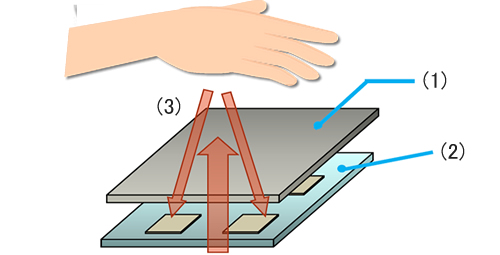

(1) Product body (PC, PET film, glass, etc.), (2) Ink for sensor, (3) Sensor module

Seamless design with ink for sensor

Ink for sensor makes possible to decorate the light receiving port of the sensor with the same color as around and create seamless design.

Process comparison between IR transmittable film and ink for sensor

Compared to IR transmittable film, ink for sensor has good cost-performance such as simple process and what is more, zero waste.

| IR transmittable film | Ink for sensor (IR transmittable ink) |

|---|---|

|

|

|

|

2. What is high functionality of ink for sensor ?

Enhanced function of ink for sensor

Today, various sensors are being used in many fields such as automobiles and electronic devices and because of this, sensors became more diversified and have higher performance. So, we are planning to enhance functionalities of ink for sensors according to diversification and higher performance of these sensors.

| Enhanced features | Details |

|---|---|

| Function of transmittable light selection |

|

| Transparency (Highly transparent IR transmittable ink) |

|

| Concealing property of visible light |

|

| Applicable to PAD printing |

|

| Weather resistance |

|

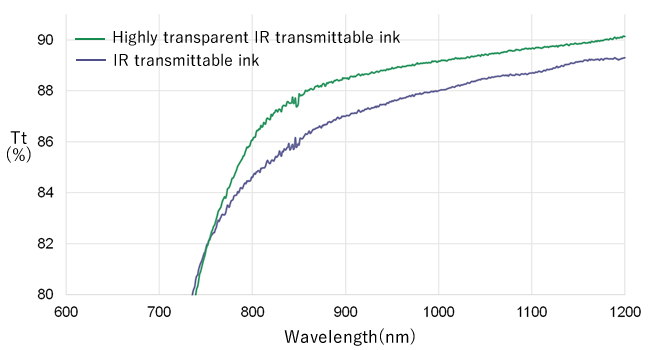

Highly transparent IR transmittable ink: Improvement of total light transmittance

Highly transparent IR transmittable ink makes already high total light transmittance further improve.

Total light transmittance (Tt (%))

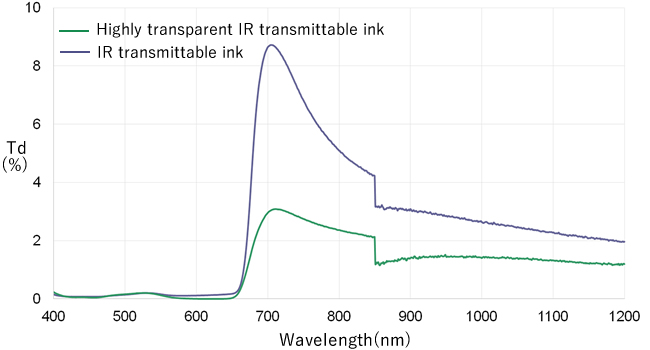

Highly transparent IR transmittable ink: Reduction of diffusion transmittance

Highly transparent IR transmittable ink realizes low haze value (high transparency) by reducing diffusion transmittance as well as improving total light transmittance.

Diffusion transmittance (Td (%))

Highly transparent IR transmittable ink: Realization of both decoration on light receiving port and highly precise images.

Highly transparent IR transmittable ink makes possible to combine decoration on a light receiving port and highly precise sensing function. The photo shows that a very clear image was obtained through the sheet on which metallic color highly transparent IR transmittable ink was printed.

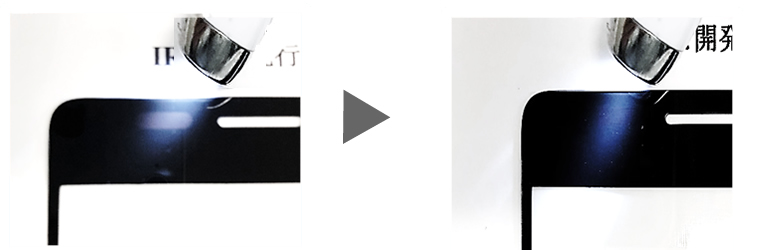

Enforcement of concealing property against visible light

Realized enforcement of concealing property against light which is contrary to IR transmittable function. The following photos show comparison between conventional ink for sensor (left photo) and ink for sensor with enforced concealing property (right photo) illuminated with light.

PAD printing with ink for sensor

Ink for sensor became applicable to PAD printing on curved glass used in smartphones, etc. The photo shows an example of PAD printing of decorative ink on curved glass. Ink for sensor also can be used for PAD printing.

3. Utilizing example of high performance ink for sensor

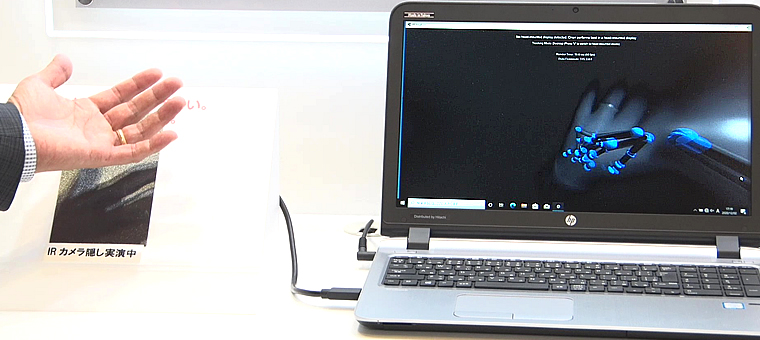

Ink for sensor can be applied to non-contact switch for infectious disease measures

Non-contact switches can be turned on and off by holding your hand over the sensor without touching it directly. This switch contains an IR sensor inside and when the sensor detects the hand, the switch is turned on and off without touching.

(1) Cover glass on which sensor ink was printed, (2) Sensor body (IC chip) (3) Infrared rays sensor receives and emits

The switch can be turned on (right photo) by simply holding your hand over the sensor (left photo) without touching it.

Utilization of sensor inks which contribute to self-driving and safe driving

A lot of sensors are used in a car in order to improve safety and wavelength to be used varies depending on the application. Please consult us whether to use sensor inks.

| Sensing object | Sensor | Detail |

|---|---|---|

| “Distance” to object |

Millimeter wave radar |

Radar using millimeter wave band |

| “Motion” of object and people | Motion sensor | Sensor detects motion of object and person (acceleration, tilt, direction, etc.) |

| Grasp objects in 3D | LiDAR sensor |

Sensor that can grasp surrounding objects three dimensionally with infrared. |

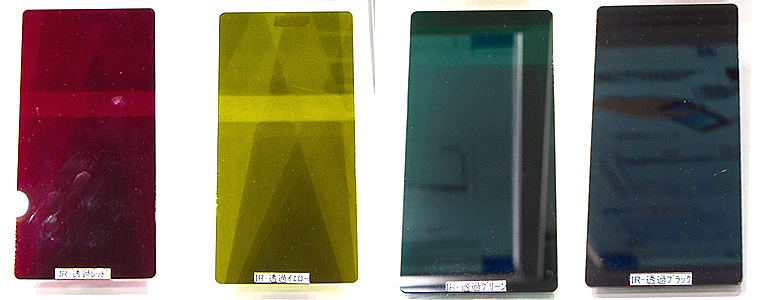

Decorating variation of sensor ink

Red, yellow, green, black and other colors can be used in sensor ink. (There are some reflections on the printed ink layers as these images were taken at the exhibition.)

Combine pearl and metallic color matched inks and IR transmittable function

Sensor ink is compatible with functional colors such as pearl, metallic and other colors those are difficult to obtain IR transmittable function. Below photos are decoration examples that the light receiving port of fingerprint authentication sensor was decorated with beautiful color matched pearl or metallic.

- Related technology information

- Related event information

- Related inks