Past events

Exhibition Report of Smart Sensing 2021

Event outline

Smart Sensing 2021 is the technology exhibition of the new social platform creating value with sensing technology. We introduced inks and printing technologies mainly for dead front printing realizing dynamic designs utilizing lights (IR transmittable ink) and sensor inks that contribute to improving sensor performance and designability and, what is more, cost reduction.

- Period

- October 27 - October 29, 2021

- Venue

- Tokyo Big site

- Official HP

- https://www.smartsensingexpo.com/

List of Exhibits

- 1. Sensor ink contributing to sensor performance, designability and cost reduction

- 2. Dead front printing (hidden printing)

- 3. Technology for non-contact switch that is effective against infectious diseases

- 4. Application of sensor ink to automobiles

- 5. Application technology of dead front printing expanding designability and functionality

- 6. Electromagnetic wave shielding ink blocking intrusion and leakage of electromagnetic waves

- 7.Click here for the exhibition video!

1. Sensor ink contributing to sensor performance, designability and cost reduction

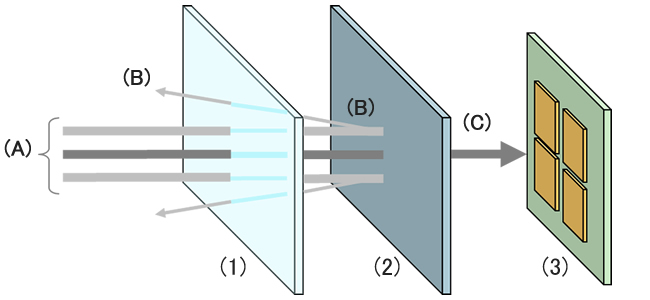

1. What is sensor ink (infrared transmittable ink/ IR transmittable ink) ?

Sensor ink, also called IR transmittable (infrared transmittable) ink, is a decorative ink that blocks visible light and ultraviolet rays causing sensor malfunction and transmits only infrared rays. By using this ink to the sensor light receiving port, it is possible to improve the accuracy and designability of the sensor. The method by printing is also excellent in respect of cost.

(A) Infrared rays, and visible light and ultraviolet rays causing malfunctions,

(B) Visible light and ultraviolet rays blocked (absorbed or reflected) by sensor ink,

(C) Transmitted infrared rays

(1)Housing of the product (PC, PET film, glass, etc.), (2) Sensor ink, (3) Sensor module

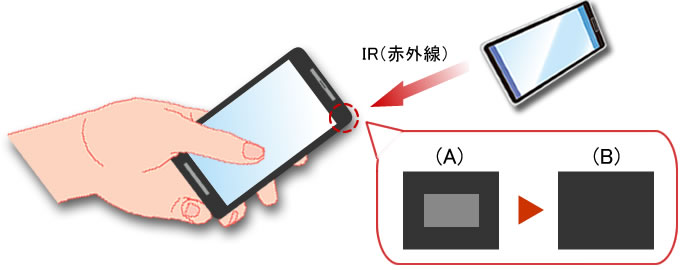

2. Improvement in designability by sensor ink

IR transmittable films were used to a conventional sensor in its light receiving port, but using this film made design limited because it had restrictions on colors and materials. But these restrictions can be solved by using sensor inks. For instance, it is possible to create a seamless design to the housing part including a light receiving port.

(A)Conventional light receiving port (design with a seam between housing device and light receiving port)

(B)Light receiving port using sensor ink (seamless design)

3. Cost reduction by sensor ink

Sensor inks also have some advantages in the manufacturing processes compared with the use of IR transmissive films. These advantages are simpler and fewer processes and what is more, no waste is generated. That’s why a significant cost reduction effect can be expected.

| Each method | IR transmittable film | Ink for sensor (IR transmittable ink) |

|---|---|---|

|

Outline of process comparison |

|

|

|

Process comparison |

|

|

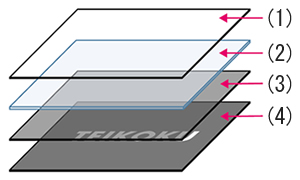

1. What is dead front printing (hidden printing) ?

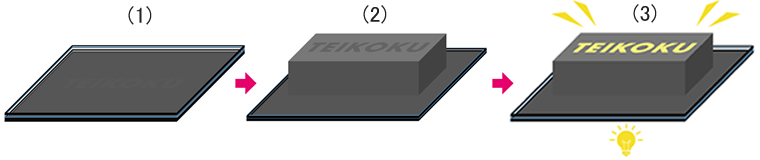

Dead front printing is a way of expression in printing that a design pops up when backlight is illuminated. Dead front printing comes to be realized when matte clear, transparent color and outline characters are printed multiply. This dead front printing makes it possible to create a design with movement that creates surprise.

(1) Front: Matte clear, (2) PC substrate, (3) Back, 1st layer: Transparent color, (4) Back, 2nd layer: outline characters

(1) Printing, (2) Molding, (3) Irradiating backlight (Characters pop up! Design with movement that creates surprise)

2. Dead front printing applicable to various base designs

Dead front printing allows you to select various colors for base and transparent colors. Piano black (jet black) or matte black can be chosen for outline characters (black base). Even an intricate design where dead front printing is applied can be vividly expressed without being lost in the base design when backlight is illuminated.

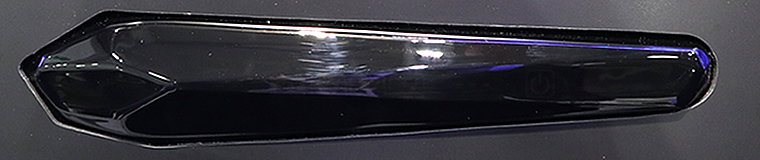

Example showing dead front printing applied to piano black (jet black)

Different colors are displayed on the right and left side. (when backlight is radiated)

Example showing an intricate design applied to dead front printing

A design with dead front printing is expressed without being affected by the base design (when backlight is irradiated)

Presented by Nakanuma Art Screen Co., Ltd.

3. Technology for non-contact switch that is effective against infectious diseases

1. What is non-contact switch effective against infectious diseases ?

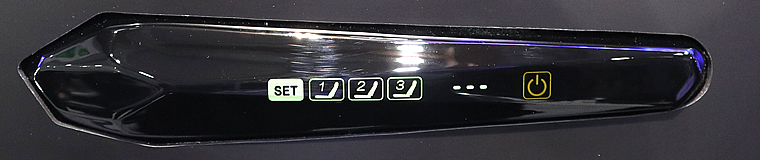

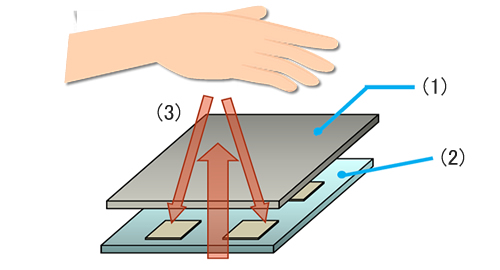

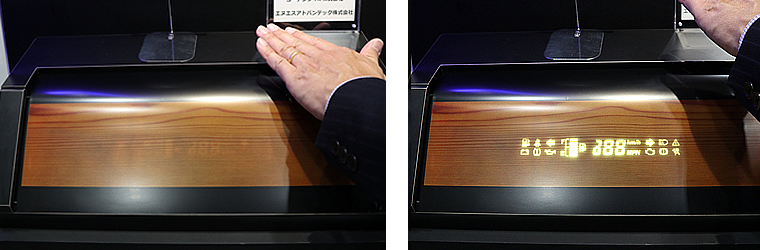

A non-contact switch is possible to turn on/off by simply holding your hand over the sensor without directly touching the part. Because a built-in infrared sensor is installed in the switch, on/off without touching is possible when the sensor detects the hand. This non-contact switch technology is supported by sensor ink (infrared transmittable ink and IR transmittable ink). By using this sensor ink, you can apply any design to the exterior of the switches. This ink can also contribute to prevent switches from malfunction as it blocks ultraviolet rays and visible light other than infrared rays.

(1) Cover glass printed with sensor ink, (2) Sensor body (IC chip),(3) Infrared rays the sensor emits and receives

A hand held over a non-contact switch (left photo). When the non-contact switch reacted (right photo)

Presented by KODENSHI TK CORP. and NS Advantech Co.,Ltd.

2. Sensor ink that expands the possibility of non-contact switches

Sensor ink is effective to expand the application range for non-contact switches because it can either hide or highlight the presence of the sensor.

| Direction of decoration | What you want to achieve | What sensor ink can support |

|---|---|---|

|

To show |

To make stand out as a non-contact switch against infectious diseases |

|

|

To hide |

To detect only specific conditions without the presence of the sensor noticed. |

|

|

To show and |

To show when it is necessary and hide when it is not necessary. |

|

4. Application of sensor ink to automobiles

1. Various sensors indispensable for safety and self-driving technology

Many sensors are equipped on a vehicle to enhance its safety these days including millimeter-wave radar grasping distance between an object and person, motion sensor grasping their movements, and LiDAR sensor grasping the surroundings in three-dimension. These are indispensable for the next-generation technologies including self-driving.

| Sensing object | Sensor | Detail |

|---|---|---|

|

“Distance” to object |

Millimeter wave radar |

Radar using millimeter wave band (wave length 1 – 10mm = frequency 30 – 300GHz) |

|

“Motion” of object and people |

Motion sensor |

Sensor detects motion of object and person (acceleration, tilt, direction, etc.) |

|

Grasp objects in 3D |

LiDAR sensor |

Sensor that can grasp surrounding objects three dimensionally with infrared. |

2. Sensor ink achieving both sensor installation and improved design

As mentioned above, it is true that installing sensor on a vehicle is essential these days, but we must avoid making a sacrifice of designability of the vehicle. Sensor ink is a technology that improve both safety and design of automobile.

Example showing the resin integrated product combining decoration and radio wave transmission (automobile emblem)

Presented by Nanbu Plastics co.,ltd.

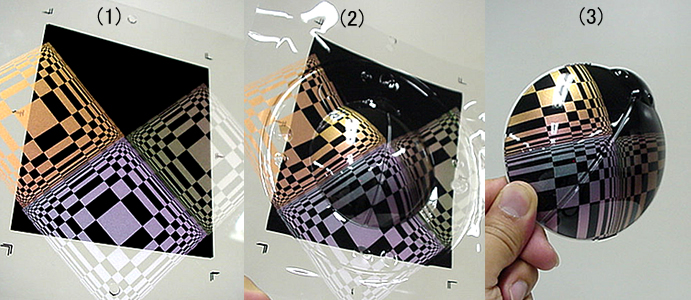

3. FIM technology that demonstrates its power in decorating three-dimensional parts equipped with sensor

FIM (Film Insert Molding) technology is used to decorate the above automobile emblems. FIM technology is a method to decorate a molded product by molding a thermoplastic resin film a design already printed on and a molding resin material integrally. In case where a light receiving port of the sensor or a part dead front printing is applied to are three dimensional shapes, decoration is possible by combining this FIM technology.

(1) Screen printing, (2) Forming, (3) Injection

5. Application technology of dead front printing expanding designability and functionality

1. Mechanism creating multiple designs by dead front printing on the same part

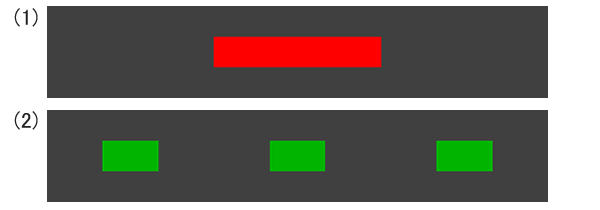

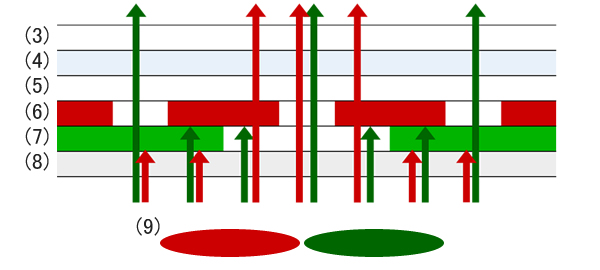

Dead front printing makes it possible to create switchable multiple designs on the same part by changing wavelength of light sources and transmittable light.

For instance, if light sources whose wavelength are aligned in red (wavelength: 580-780nm) and green (wavelength: 490-580nm) were backlighted, inks selectively transmitting each light source (ink transmitting only red light, ink transmitting only green light, transparent part transmitting both) are combined with each other to draw the image. As a result, it is possible to display the image where red light transmitted when the red light was irradiated and the image where the green light transmitted when the green light was irradiated on the same part.

(1) Image when red light was irradiated, (2) Image when green light was irradiated

The mechanism combining those inks which only transmit red light, which only transmit green light, which transmit both lights, and which transmit neither light

(3) Substrate, (4) Transparent ink, (5) Smoky color ink, (6) Ink transmitting only red wavelength, (7) Ink transmitting only green wavelength, (8) Diffusion ink, (9) Two light sources of red and green

2. Switching images by red and green light sources on the same part

Using the mechanism above makes it possible to create two images by switching red and green light sources on the same part. The following is an example showing two types of designs displayed when red light is irradiated and when green light is irradiated on the large molded product resembling the rear side of the vehicle.

Beautiful jet black applied on the entire surface (no backlight irradiation)

Geometric pattern in red and STOP sign (when red light is illuminated)

Design with plant in green and MOVE sign (when green light is illuminated)

Hidden two designs emerged (when two lights of red and green are irradiated)

Presented by Asano Laboratories Co., Ltd.

6. Electromagnetic wave shielding ink blocking intrusion and leakage of electromagnetic waves

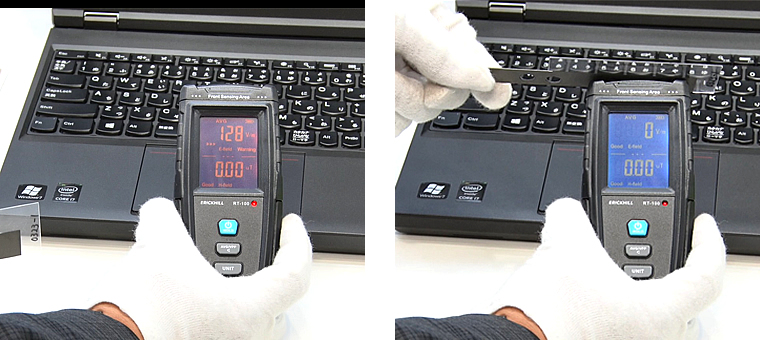

1. What is electromagnetic wave shielding ink ?

Electromagnetic wave shielding ink is a kind of conductive ink which makes conductive printed ink layer block (shield) intrusion or leakage of electromagnetic wave. With this ink, it is possible to prevent electromagnetic waves interfering with the sensor and leaking from the sensor equipped device only by a simple process printing.

The following is an example that the printed material using electromagnetic wave shielding ink shields electromagnetic waves (radiation electric field was measured) radiating from the PC display. The radiation electric field is shielded from measured value in normal time (128 (V/m)) (left photo) to unmeasurable value (0 V/m) (right photo).

(Exhibition Report on 13th Automotive World)

2. Advantages of printing system

Shielding electromagnetic waves by printing is a superior method in resistance, lighter and thinner, and process reduction compared with other methods using metal foil or the like.

| Excellent features | Details |

|---|---|

|

High moisture resistance, lightweight and thin |

|

|

Inexpensive and flexible screen printing |

|

|

Achieve both decoration and other functions |

|

7.Click here for the exhibition video!

- Related technical information

-

- Ink for sensor realizes even higher performance

- Ink for sensor

- Introduction of IR transmittable ink (IR Transmitting Ink) and concealed printing

- Technology lecture for FIM/IMD 1st session: Explanation of the merit and 3 process.

- Conductive ink that allows free setting of resistance value

- Introduction of GLS-HF ink(2)

- High Definition Ink System for Molding

- Electromagnetic wave shielding ink

- Related event information

Please feel free to contact us about the inks, methods, and trial products we have introduced.