Past events

Exhibition Report of 13th Automotive World

Event outline

13th Automotive World is a technology exhibition covering latest technologies in the automotive industry such as self-driving, digitization and motorization of automotive, connected car, and lightweight, etc.

We introduced sensor inks which contribute to self-driving and safe driving, as well as latest technologies of inks and printing such as dead front printing (concealing printing), FIM technology and electromagnetic wave shielding inks which contribute to improvement of designability, lightweight and cost reduction.

- Period

- January 20 - January 22, 2021

- Venue

- Tokyo Big site

- Official HP

- https://www.automotiveworld.jp/en-gb.html

List of Exhibits

- 1. Introduction of sensor inks that contribute to self-driving and safe driving

- 2. Introduction of dead front printing (concealing printing), which can hide design

- 3. Introduction of decoration technology to non-contact switch which is effective in infection preventive measures

- 4. Introduction of application technology which improves designability and functionality

- 5. Introduction of FIM technology decorating curved display beautifully

- 6. Introduction of film wrapping by screen printing, which contributes to lightweight and cost reduction

- 7. Introduction of electromagnetic wave shielding ink as an inexpensive and lightweight countermeasure against electromagnetic waves

- 8. Introduction of FIM technology which decorates 3D object beautifully and inexpensively

- 9. Introduction of high transparency IR transmittable ink applicable to high performance sensors

- 10.Click here for the exhibition video!

1. Introduction of sensor inks that contribute to self-driving and safe driving

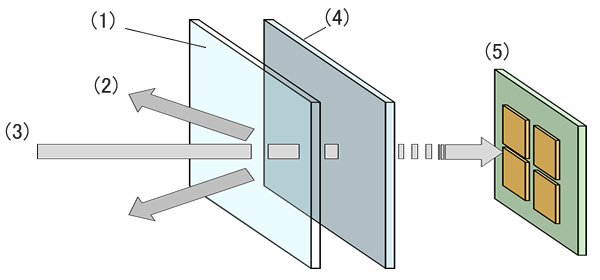

1. What is sensor ink (infrared transmittable ink, IR transmittable ink) ?

Sensor ink is a decorative ink which has ability to transmit light the sensor should detect (infrared rays, etc.). This ink enables us to add the same decoration to the sensor port as the around area. Thanks to that, both sensor function and seamless design which were difficult before become possible.

In addition, sensor ink contributes to improvement of functionalities such as prevention of sensor malfunction because sensor ink can prevent transmission and diffused reflection of ultraviolet rays or visible light.

(1) Product body (PC, PET film, glass), (2) Visible light, ultraviolet rays causing malfunction

(3) Light of wavelength to be detected (Infrared rays), (4) Sensor ink, (5) Sensor module

2. Sensor ink indispensable for safety and self-driving technologies

In order to improve the safety of vehicles and realize self-driving, it is necessary to equip many sensors in a vehicle. For example, millimeter wave radar reading the distance between an object and a person, a motion sensor grasping those movements, and LiDAR sensors grasping those surrounding conditions three-dimensionally.

Sensor ink contributes to improvement of both decoration and functionality of various sensors which are indispensable for improvement of safety and self-driving.

| Sensing object | Sensor | Detail |

|---|---|---|

|

“Distance” to object |

Millimeter wave radar |

Radar using millimeter wave band (wave length 1 – 10mm = frequency 30 – 300GHz) |

|

“Motion” of object and people |

Motion sensor |

Sensor detects motion of object and person (acceleration, tilt, direction, etc.) |

|

Grasp objects in 3D |

LiDAR sensor |

Sensor that can grasp surrounding objects three dimensionally with infrared. |

Example of decoration on the emblems transmitting millimeter wave radars

Example of beautiful blue color printed on the surface of metal tone

Presented by Meieisha Co., Ltd.

2. Introduction of dead front printing (concealing printing), which can hide design

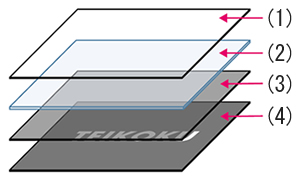

1. What is dead front printing (concealing printing) ?

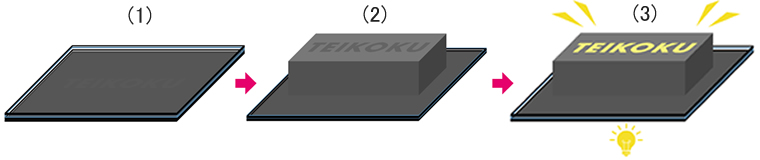

Dead front printing (concealing printing) is a printing expression that a design appears when backlight is illuminated. Dead front printing (concealing printing) can be produced by multi-layer printing of matt clear, transparent color and outline pattern. Dynamic designs which create surprises is possible by this dead front printing (concealing printing).

(1) Front: Matt clear, (2) PC substrate, (3) Back 1st layer: Transparent color, (4) Back 2nd layer: Outline pattern

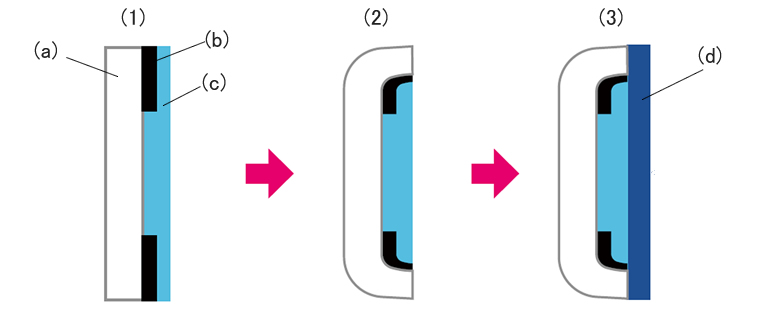

(1) Printing, (2) Molding, (3) Backlight illumination (Characters appear! (Dynamic design creates surprises))

2. Applicable to black base, white base and metallic base

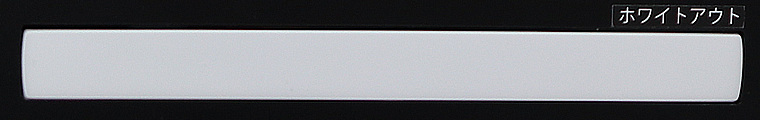

Dead front printing (concealing printing) enables you to select various colors for the base color and transparent color. For black base, piano black (jet black) or matt black, etc. can be selected. Dead front printing (concealing printing) can also be applied to white base or metallic color base.

Dead front printing (concealing printing) is a versatile technology such as contributing to cost reduction and lightweight by replacing LCDs of automobile indicators with LEDs.

Example of Dead front printing (concealing printing) applied to white base

Example of Dead front printing (concealing printing) where multiple transparent colors with metallic color base were applied

3. Image switching (changing) on the same part by combining LED light sources

Dead front printing (concealing printing) enables you to apply different (changing) images to the same part by using LED light sources with equal wavelength. The following is an example of two types of designs when red light was irradiated and when blue light was irradiated were applied on the same part.

3. Introduction of decoration technology to non-contact switch which is effective in infection preventive measures

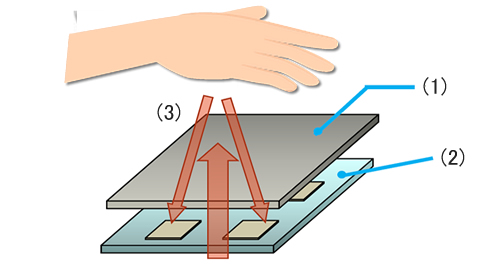

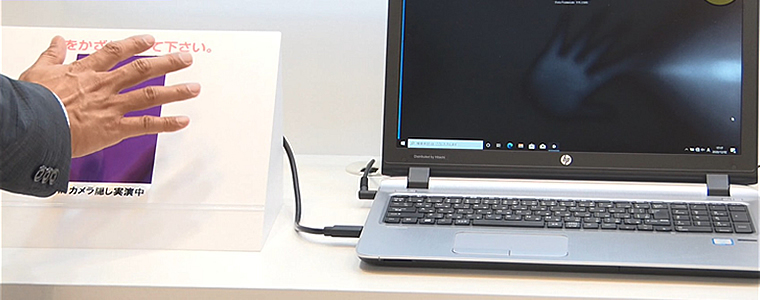

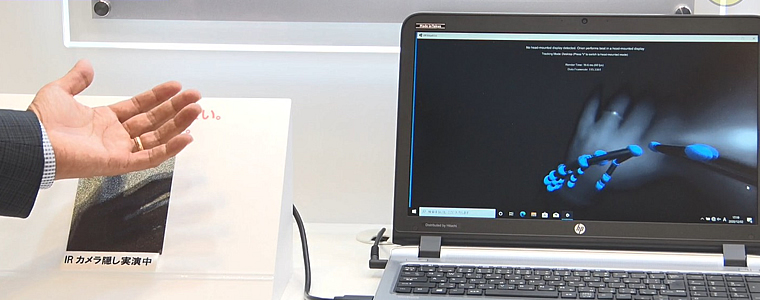

1. What is a non-contact switch effective in infection preventive measures ?

A non-contact switch is a switch that can be turned on and off by simply holding your hand over it without touching the part directly.As an infrared sensor is equipped with the switch, the device can be turned on and off when the sensor detects the hand.

It is the sensor ink (infrared transmittable ink and IR transmittable ink) which supports this non-contact switch technology. By using this sensor ink to non-contact switch, it is possible to freely design and hide the sensor built into the exterior packaging. Furthermore, this ink contributes to improvement of switch functionalities such as preventing the switch from malfunctions due to intruding ultraviolet rays and visible light.

(1) Cover glass on which sensor ink was printed, (2) Sensor body (IC chip), (3) Infrared rays that the sensor emits and receives

A hand held over the non-contact switch (left photo). The non-contact switch reacted to the hand (right photo)

4. Introduction of application technology which improves designability and functionality

1. Achieve both sophisticated printing expression and dead front printing (concealing printing)

In addition to setting base colors and transparent colors freely, complicated designs such as delicate molding with fine lines can be added to dead front printing (concealing printing). Therefore, it is possible to create an expression with a stage effect by hiding it when it is unnecessary and draw an elaborated luxurious design with light only when it is necessary.

Jet black design when blacked out (no backlight)

Beautiful design with fine lines standing out against jet black (when backlight is illuminated)

2. Realize both elaborated printing expression such as wood grain texture and dead front printing (concealing printing)

Dead front printing (concealing printing) is possible to realize both wood grain texture making full use of gradation and jet back design. So new functions such as light creation and status display can be newly added to the area where the elaborate design was already decorated.

Application example of luxurious wood grain texture and jet black design (when backlight is illuminated (right photo))

Presented by Nakanuma Art Screen Co., Ltd.

3. Realize both luxuriousness and functionality by combination of leather texture and dead front printing (concealing printing)

Dead front printing (concealing printing) enables you to add new design and functionality to high designable materials. The following is an example of transmittable artificial leather. Transmittable artificial leather is a technology combining material (urethane system) realizing designability like real leather and concealing printing. By using this technology, it is possible to create an unprecedented design realizing both luxuriousness of leather and functionality.

Example of transmittable artificial leather with luxurious design to which concealing printing is applied (when backlight is illuminated (right photo))

Presented by Sakaiya Co., Ltd.

5. Introduction of FIM technology decorating curved display beautifully

1. What is a resin made curved display with excellent designability and lightweight ?

The more we pursue improvement in safety, living space and designability, the more curved displays manufactured by molding resin have been used for display panels of driver’s seats for vehicles. By using curved display, we became easy to create designs meeting with conditions inside the vehicle and also realized lightweight display panels. It is FIM (Film Insert Molding) technology which beautifully decorates the frames of this curved display.

FIM technology decorating a molded display frame with complicated shape

2. What is FIM (Film Insert Molding) ?

FIM (Film Insert Molding) is a method to decorate the molded article by molding thermoplastic resin on which design was already printed and materials for resin molding integrally. Compared with painting, this method has excellent features such as simple process and low cost, and high flexibility of design (multi colors and fine lines are possible), etc.

(1) Screen printing, (2) Forming, (3) Injection

(a) Thermoplastic resin film, (b) Printed ink layer, (c) Binder layer, (d) Molding resin

6. Introduction of film wrapping by screen printing, which contributes to lightweight and cost reduction

1. What is film wrapping by screen printing ?

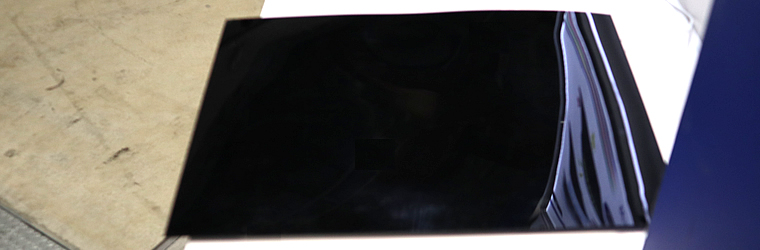

Film wrapping which is also called car wrapping, is a method to express designs and texture freely by attaching dedicated films to a car body.

Specially, by using screen printed film, you can add not only deep colors like painting but also multicolor designs which are impossible for painting. The process of film wrapping is easier and cheaper than that of painting and it is a technology that expands the degree of freedom of customization, such as changing the exterior of your beloved car every few years.

2. Applicable to lightweight of car body, environmental measures and cost reduction

As lightweight of vehicles has been sought, exterior materials (CFRP, etc.) which are difficult to be painted have been used in today’s automobiles. Film wrapping is the method that can be applied to various materials like these at low cost. Furthermore, compared with painting, film wrapping is eco-friendly method as it does not emit environmentally hazardous substances.

7. Introduction of electromagnetic wave shielding ink as an inexpensive and lightweight countermeasure against electromagnetic waves

1. What is electromagnetic wave shielding ink ?

Electromagnetic wave shielding ink is a kind of conductive ink which makes conductive printed ink layer block intrusion or leakage of electromagnetic wave. The higher conductivity is, the higher performance of electromagnetic shield becomes. By using this ink, it is possible to add an electromagnetic wave shielding function by printing.

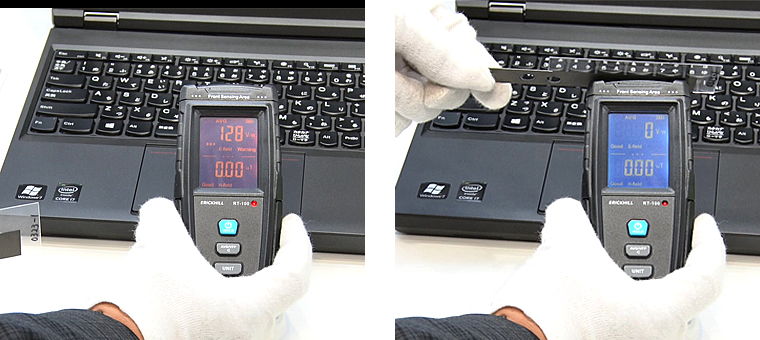

The following is an example that the printed material using electromagnetic wave shielding ink shields electromagnetic waves (radiation electric field was measured) radiating from PC display. The radiation electric field is shielded from measured value in normal time (128 (V/m)) (left photo) to unmeasurable value (0 V/m) (right photo).

2. Advantages of printing

Compared with other methods using a metallic foil, electromagnetic wave shield by printing is an excellent method in cost reduction and lightweight. In addition, it is possible to apply customizations such as achieving both printing only necessary parts and light transmission by mesh printing, which are difficult with other methods. Moreover, it has excellent resistance to humidity.

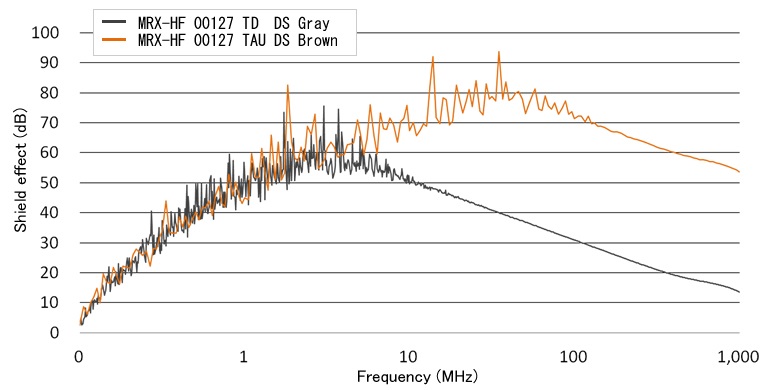

3. Performance of electromagnetic wave shielding ink

| Ink name | Surface Resistance Ω |

0.3 – 3 MHz |

3 – 30 MHz |

30 – 300 MHz |

0.3 – 1 GHz |

|---|---|---|---|---|---|

|

MRX-HF 00127 TD DS Gray |

100Ω |

30 – 60dB |

40 – 60dB |

20 – 40dB |

18 – 22dB |

|

MRX-HF 00127 TAU DS Brown |

1Ω |

40 – 65dB |

65 – 80dB |

65 – 80dB |

50 – 60dB |

Shield performance value of electromagnetic wave shielding ink

Test conditions: Ink layer thickness 15µm,

tested substrate PC, drying conditions 80°C for 30 min

Printing conditions:

Gray T-250 Mesh, Z-004 Solvent 5%, 210 Catalyst 5%

Brown T-250 Mesh, SM-800 Additive 10%, 210 Catalyst 5%

8. Introduction of FIM technology which decorates 3D object beautifully and inexpensively

1. FIM technology showing its ability on decorating elaborate 3D objects

FIM (Film Insert Molding) is a technology used to decorate frames of curved display mentioned above. This FIM technology also shows its ability on decorating 3D objects with uneven complicated shapes and multicolored design.

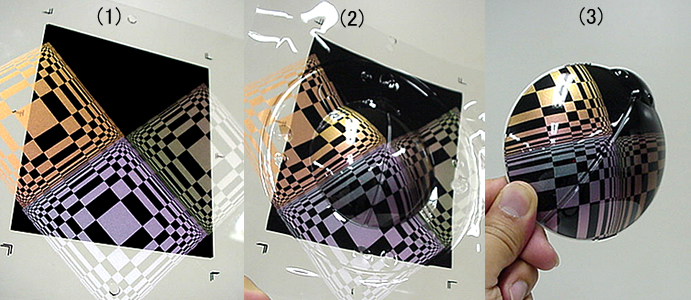

For example, decoration to intricate articles and decoration using multiple colors are very difficult processes with painting technology. However, FIM technology makes it easier because you can decorate the article by printing and forming like below photos.

(1) Screen printing, (2) Forming, (3) Injection

2. FIM technology realizing major cost reduction by integrating multiple parts

FIM also has a technology that integrates multiple parts with different colors and textures by printing and forming. This integrating technology can drastically reduce processes and cost.

High Definition ink (high definition screen ink) which can print 100µm fine lines and dots with high quality is also compatible with FIM technology and it enables us to select expression from various ways.

Example that High Definition ink (high definition screen ink) for FIM ink is used

3. FIM molding ink supporting FIM technology

FIM molding ink which supports FIM technology is FIM molding ink and it has excellent resistance to heat and elongation. FIM molding inks specialized for various functions depending on your needs are available.

| Product name | Type | Features | Example for use |

|---|---|---|---|

|

(High Definition Ink) |

2 pack type |

100 µm thin lines can be printed with high accuracy |

2 or 4 wheel vehicle nameplates, home appliances, kitchenware nameplates, mobile phones and computers |

|

2 pack type |

High speed printing, resistance to yellowing from heat |

Home appliances, kitchenware nameplates, washing machines, refrigerators, vacuum cleaners, microwave ovens, rice cookers |

|

|

2 pack type |

Resistance to ink flow, excellent resistance to ink layer |

2 or 4 wheel vehicle nameplates, home appliances, kitchenware nameplate, mobile phones and computers |

|

|

2 pack type |

Applicable to PP and TPU substrate, flexibility |

2 or 4 wheel vehicle nameplates, motorcycle cowls, touch panels, housings |

|

|

1 pack type |

Excellent elongation, workability |

2 or 4 wheel vehicle nameplates |

|

|

1 or 2 pack type |

Transparency, mirror finish retention, leveling |

LCD front face plate for pachinko and slot machine |

|

|

2 pack type |

Transparency, crack resistance, over printing ink for MIR |

Mobile phones, ITO film protective layer |

|

|

1 pack type |

Binder ink for 2 pack type ink (Adhesive layer between molding resin and printed ink layer) |

|

9. Introduction of high transparency IR transmittable ink applicable to high performance sensors

1. What is high transparency IR transmittable ink ?

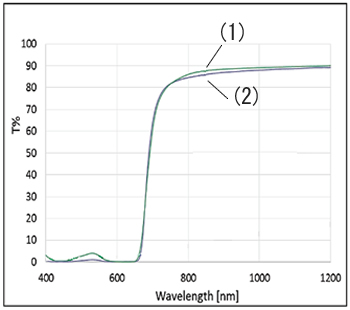

Compared with conventional IR transmittable ink, high transparency IR transmittable ink is the ink which increases the amount of transmitted light and decreases light diffusibility which causes malfunction. This ink realizes improvement of both functionality and designability to meet the sensors whose performance has been improving for self-driving. The following is the comparison of transmittance and diffusibility of high transparency IR transmittable ink and conventional ink.

|

All rays transmittance (1)High transparency IR transmittable ink, (2) Conventional IR transmittable ink |

Diffusibility (diffuse transmittance) (1)High transparency IR transmittable ink, (2) Conventional IR transmittable ink |

|

|

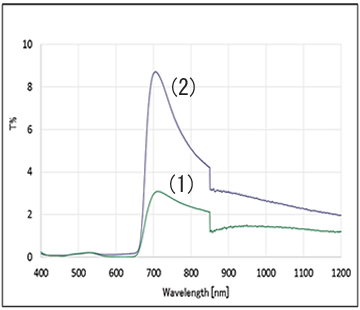

2. Image comparison between high transparency IR transmittable ink and conventional IR transmittable ink

The following is an image comparison that high transparency IR transmittable ink and conventional ink were actually used for the motion sensor. Compared with conventional ink (upper photo), high transparency IR transmittable ink (lower photo) detects the shape of the hand more clearly.

10.Click here for the exhibition video!

- Related technical information

-

- Ink for sensor

- Introduction of IR transmittable ink (IR Transmitting Ink) and concealed printing

- Technology lecture for FIM/IMD 1st session: Explanation of the merit and 3 process.

- Introduction of VK Ink Series

- Introduction of GLS-HF ink(2)

- High Definition Ink System for Molding

- Electromagnetic wave shielding ink

- Related event information

Please feel free to contact us about the inks, methods, and trial products we have introduced.