Past events

Exhibition Report of Converting Technology Exhibition 2017

Event outline

"Converting Technology Exhibition" is the exhibition on processing technology of web sheet materials such as film sheet, metal foil, paper, paper board, non-woven fabric and artificial paper, etc. (converting technology) and materials and devices.

In this exhibition, we introduced our latest printing and ink technology by focusing on High Definition Ink (High Quality and High Definition Screen Ink) we announced in July 2016.

- Period

- February 15 - 17, 2017

- Venue

- Tokyo international exhibition center (Tokyo Big Sight)

- Official HP

- http://convertechexpo.com/en/index.html

List of Exhibits

- 1. Introduction of excellent decoration property in High Definition Ink (High Quality and High Definition Screen Ink)

- 2. Introduction of excellent printing quality of High Definition Ink

- 3. Introduction of cost reduction by excellent continuous printability in High Definition Ink

- 4. Introduction of Highly Brilliant Mirror Ink (Mirror effect ink)

- 5. Introduction of Piano Black (jet black) ink producing high-grade sense

- 6. Introduction of Clear which can control optical property freely

1. Introduction of excellent decoration property in High Definition Ink (High Quality and High Definition Screen Ink)

Realization of simultaneous printing of beautiful solid pattern, very fine line and high resolution gradation:

High Definition Ink realized printing of 100µm(=0.1mm)fine line and gradation printing of over 130-lpi(line per inch). These fine line and gradation also can be printed in the same stencil as solid pattern.

Application:

Automotive interior, home appliances, and smartphones

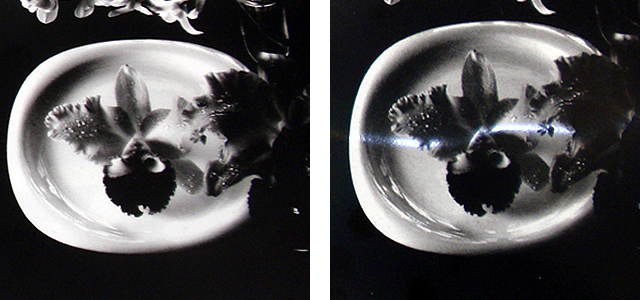

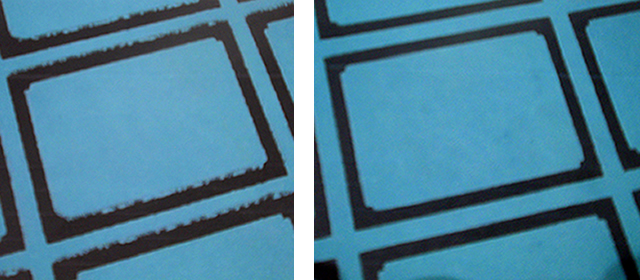

Comparison of gradation printing in conventional ink (left side photo) and 175-lpi(line per inch) of gradation printing in High Definition Ink (right side photo)

In conventional ink (left side photo), fine dot has not been printed and looks whitish. In High Definition Ink (right side photo), light running crossways is reflection light at the time of photographing.

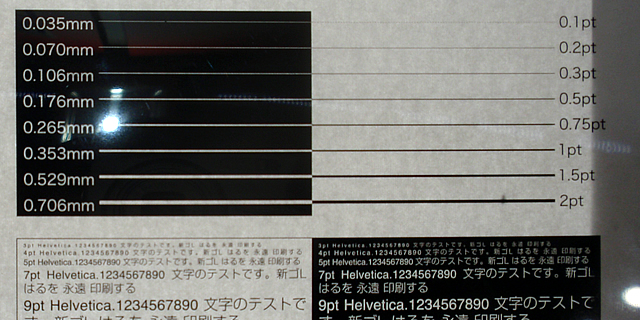

High Definition Ink enables beautiful printing of 0.035mm level fine line (including outline printing).

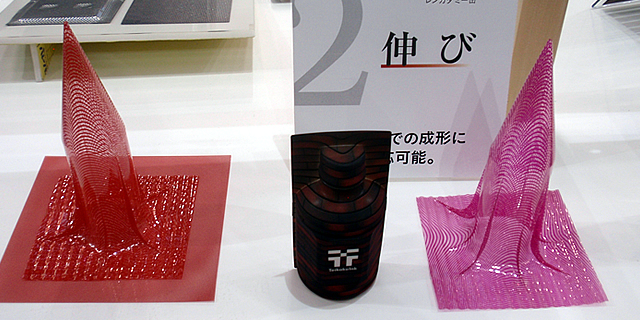

High Definition Ink realizing both fine line printing and molding

2. Introduction of excellent printing quality of High Definition Ink

High printing quality realizing very beautiful printed boundary without concavo-convex:

In conventional screen ink, there was problem of serrated concavo-convex occurred in printed boundary part (lower left side photo). High Definition Ink solved this problem and realized smooth printed boundary (lower right side photo).

Application:

Automotive interior, home appliances, smartphones, and electronic parts

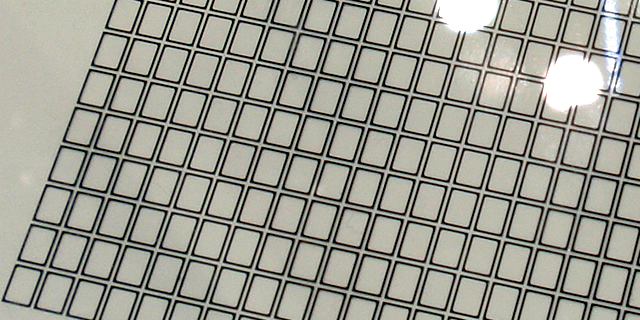

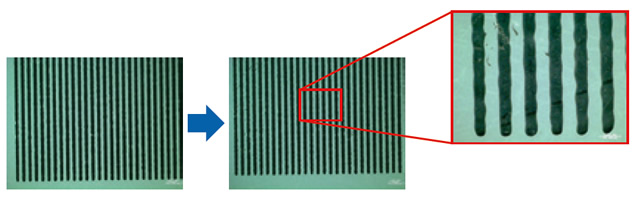

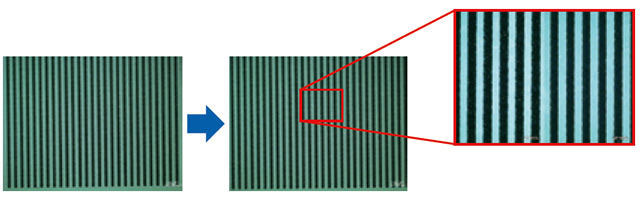

Example of continuous printing of fine lattice pattern (line width: 200µm) on glass

Comparison of printing quality in conventional ink (left side photo) and High Definition Ink (right side photo)

3. Introduction of cost reduction by excellent continuous printability in High Definition Ink

Shortening operation hours by reduction of the number of cleaning in stencil:

High Definition Ink providing excellent continuous printability can significantly reduce the number of cleaning stencil during continuous printing.

For example, this ink enables reducing frequency of cleaning stencil to one- fifth: every 300 sheets to every 1500 sheets (please refer to the following chart). Consequently, working hours can be shortened and it enables both high quality and cost reduction.

Application:

Printed sample by cylinder printing

Example of high-speed and continuous printing

(Printing conditions: Cylinder press 1500 sheets/hour, polyester L355 mesh, thread diameter 27µm)

Conventional ink: Defect such as ink spatter occurred at printing 10 sheets (left) – 300 sheet (right).

High Definition ink: Defect does not occur at printing 10 sheets (left) – 1500 sheet (right).

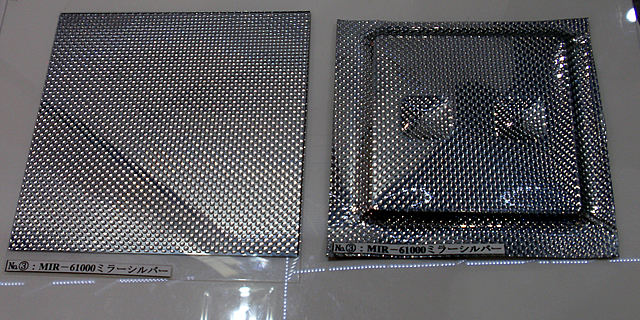

4. Introduction of Highly Brilliant Mirror Ink (Mirror effect ink)

This ink realizes beautiful mirror effect like a mirror on glass:

MIR-61000 Mirror Silver is mirror ink realizing both printing on glass and beautiful mirror effect. As for realizing beautiful mirror effect on resin sheet, MIR-51000 is applicable.

Unlike metal plating, both mirror inks do not contain hazardous substance such as cyanogen compound or chrome and are applicable to strict environmental regulations.

Application:

Automotive interior, home appliances, smartphones

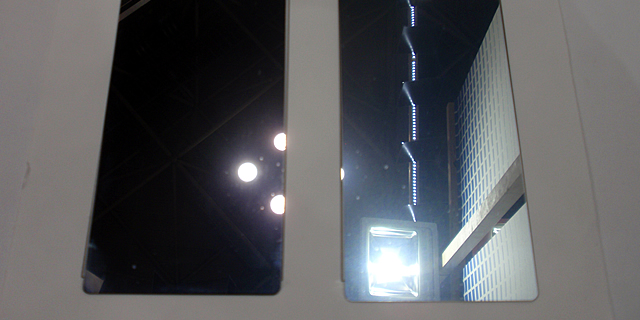

Mirror Ink realizing surface like a mirror

MIR-61000 MIRROR SILVER (left side photo), MIR-51000 MIRROR SILVER (right side photo)

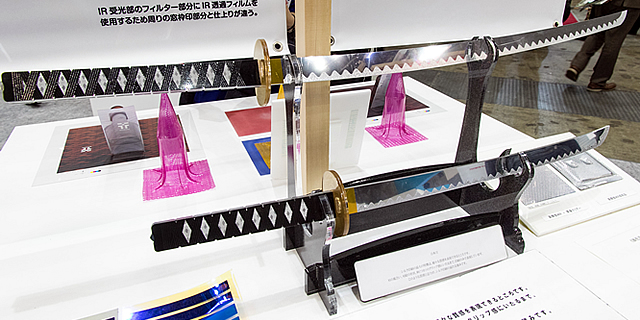

Print Thick Layer Clear on Highly Brilliant MIR ink (left side photo), Molded article of Highly Brilliant MIR (right side photo)

Japanese sword utilizing metallic gloss of Mirror Ink

5. Introduction of Piano Black (jet black) ink producing high-grade sense

Producing high-grade sense by black like Japanese:

This jet black ink realizes glossy black finish called “piano black” or “jet black”. The ink provides gloss with high-grade image or unique brightness like Japanese lacquer and contributes to high value addition to products.

Application:

Automotive interior, home appliances

Black molded article like Japanese lacquer produced by film insert molding. Ceiling view is projected on jet black surface.

Introduction of the relevant technical reports:

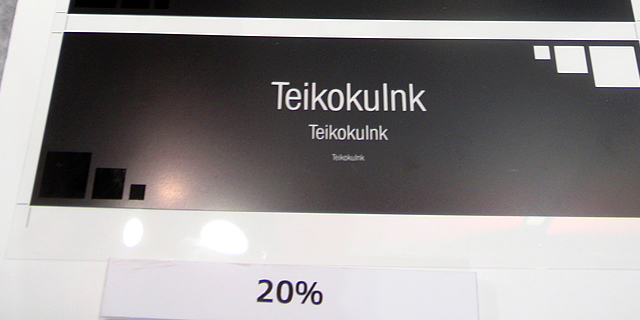

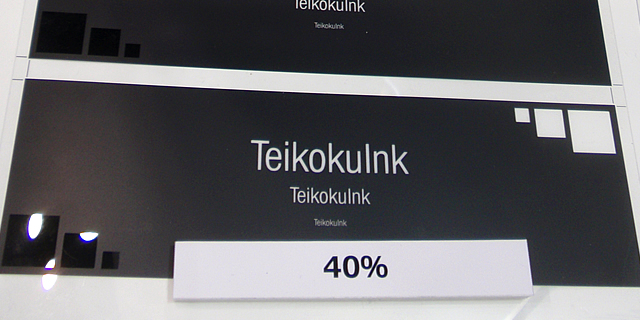

6. Introduction of Clear which can control optical property freely

Clear realizing both anti-glare (low reflection) function and high transparency:

MIX-HF Ink is screen ink providing high transparency and excellent leveling function. Providing anti-glare (low reflection) function to this MIX-HF ink realizes utilization as Clear with very high visibility.

Application:

Automotive meter, home appliance display panel

It is possible to adjust anti-glare (low reflection) function in accordance with application.

Compare to upper photo (controls 20%), this Clear further controls reflection light (40% as seen in the lower photo as follows).

- Related technical information

-

- Introduction of 7 benefits

- Introduction of functional Black ink

- Introduction of High Quality and High Definition Screen Printing Ink

- Introduction of High-Definition Ink (high-quality, high-definition screen ink)

- MIR-51000 Mirror Silver

- Introduction of MIX-HF(1)

- Introduction of MIX-HF(2)

- Introduction of MIX-HF ink(3)

- Related event information

Please feel free to contact us about the inks, methods, and trial products we have introduced.