Realization of High Quality/High Definition printing and high molding properties.

High Definition Ink System for Molding

Good news to those in charge of development of automobile interiors where high quality is required.

We will introduce the compatibility of solid printing with fine printing, beautiful gradation, and uniformity and excellent molding function realized by High Definition Ink System for molding.

1. Decoration method for molded component

Film Insert Molding (FIM/IMD) realize free design for three-dimensional object.

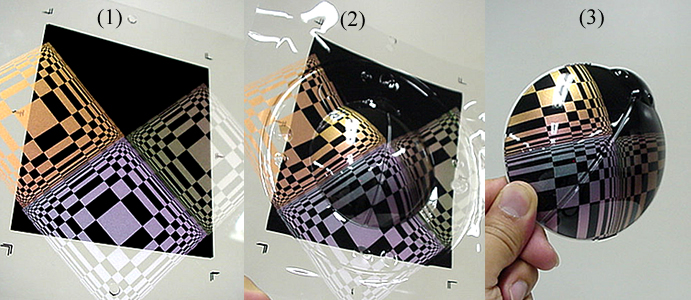

FIM/IMD decorates in three steps, (1) Printing process, (2) Forming process and (3) Injection process. Decoration by these three processes makes it possible to design with high degree of freedom unlike painting etc. due to decoration by printing.

- Screen Printing Process:

Decorative printing on thermoplastics resin film. - Forming Process:

Heat and soften preliminarily extruded molding sheet, set to mold before cooling and solidification, trimmed (finishing) after forming to final shape with vacuum pressure or compressed air. - Injection Process:

Insert it into a predetermined mold, heated, molten and fluidized molding resin material into a mold by applying pressure, and solidify by cooling to integrate the printing sheet and molding resin material.

In addition to FIM / IMD, there is a method without injection process but (1) printing and (2) forming process. Even in this case, decoration with high degree of freedom is possible due to decoration by printing.

2. Realization of High Quality/High Definition decorations on molded articles by High Definition Ink System

Realize both High Quality/High Definition Printing and molding property.

Decorating method by printing and molding such as FIM / IMD has always been expected to realize the intended design with high precision because design freedom is very high.

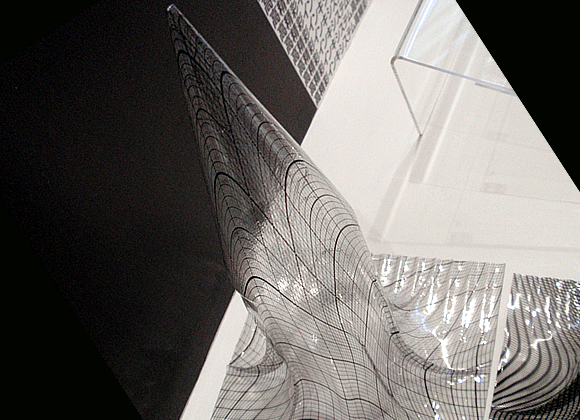

To meet the requirement for such high precision, High-Definition Ink System for molding have responded by combining high-quality and high-definition printing with excellent molding functions. With the compatibility of these two functions, it became possible to realize high precision decorations on molded products such as gradation with dots of 100 µm level, fine lines with width of 100 µm level, beautiful solids without unevenness, etc.

Below is an example of forming a film printed with fine lines with different thicknesses of 100 µm level. No wire disconnection or the like is seen after molding, maintaining a beautiful lattice pattern while maintaining the initial thickness difference.

Characteristics of High Definition Ink Systems for molding.

The High Definition Ink System for molding, XFM (forming ink), XIP-HF (ink for FIM / IMD) has the following features.

| Item | XFM | XIP-HF |

|---|---|---|

| Product Description | One pack type for forming High Definition Ink System |

Two pack type for insert molding High Definition Ink System |

| Characteristics | Superior flexibility of printed ink layer during post process Superior resistance for vacuum forming Superior printing stability and high speed printing property |

Superior heat resistance during post process Good adhesive property to treated PET, PC. Non-use of Halogen compound (Chlorine Cl, Bromine Br) |

| High Quality High Definition |

Faithful reproduction of solid and fine patterns Printing fine lines of 100 µm with high accuracy (One side sagging width: 8µm or less) |

Faithful reproduction of solid and fine patterns Printing fine lines of 100 µm with high accuracy (One side sagging width: 8µm or less) |

| Printing Substrate | PC, PMMA | Treated PET, PC |

| Application | Automobile nameplate | Automobile nameplate. Appliances |

3. Example of superior molding property of High Definition Ink System

Realization of High Quality/High Definition gradation and molding

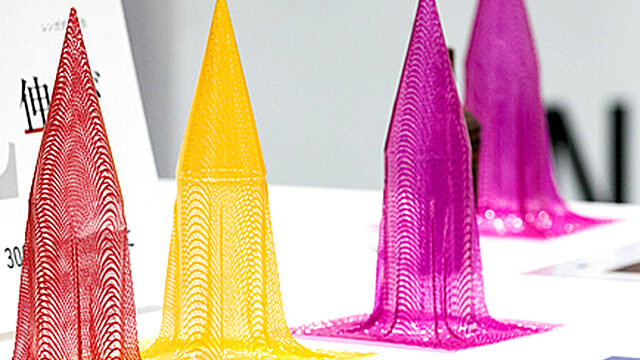

We maintain a texture that achieves a gradation with a dot diameter of 100 µm even after molding.

It is compatible with vivid, fine-grained gradation and molding. Extend the range of design further.

A case of a large molded product in which a solid and a gradation are printed in one stencil.

In the past, it was necessary to separate plates with solid and gradation, but High Definition Ink System can be printed in one stencil.

- Related technology information

-

- 180: Introduction of High-Definition Ink (high-quality, high-definition screen ink)

- 178: Introduction of 7 benefits

- 177: Introduction of High Quality and High Definition Screen Printing Ink

- 175: Introduction of new decoration of PP resin products.

- 150: Technology lecture for FIM/IMD 1st session: Explanation of the merit and 3 process.

- Related event information

- Related inks