Past events

Exhibition Report of Converting Technology Exhibition 2019

Event outline

"3D surface decoration technology exhibition" having a theme of technology and materials that adds designability and functionality of the products was held at "Converting Technology Exhibition 2019". We, at this technology exhibition, exhibited latest printing and ink technology such as High Definition Ink (high-quality and high-definition screen ink), etc. adding high grade image to the products.

- Period

- January 30 - February 01, 2019

- Venue

- Tokyo Big site

- Official HP

- http://convertechexpo.com/en/index.html

List of Exhibits

- 1. Introduction of ink for sensor supporting automation and safety improvement

- 2. Introduction of new designs utilizing light

- 3. Introduction of realization of high grade image by highly accurate printing and High Definition Ink System

- 4. Introduction of adding high grade image by means of reproducing real material feeling

- 5. Introduction of decoration to 3D (three-dimensional object) and improvement of designability by substitute for painting

- 6. Introduction of functional clear which gives various resistance and functionalities

1. Introduction of ink for sensor supporting automation and safety improvement

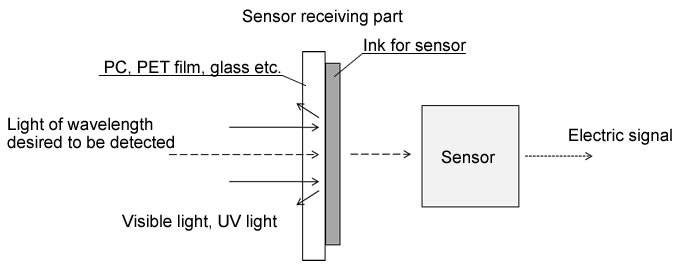

1. Ink for sensor applicable to various sensors

Ink for sensor (infrared transmittable ink (IR transmittable ink)) is the ink that has functions of transmitting wavelength (infrared ray, etc.) to be detected by sensor and intercepting other wavelengths (visible light and UV-ray, etc.). This ink achieves both prevention of sensor malfunction and free decoration to the light receiving port.

- Mechanism of ink for sensor

-

2. Ink for sensor applicable to various car sensors

Many sensors have been used in modern automobiles to enhance safety and comfortability. Our ink for sensor contributes to the improvement of sensor accuracy as well as giving free decoration to a light receiving port of sensor by transmitting only wavelength those sensors should detect.

| Target of detection | Sensor name | Description |

|---|---|---|

|

Distance to object |

Millimetric wave radar |

Radar using electric wave of millimeter band |

|

Object movement |

Motion sensor |

Sensor detecting object movement (acceleration/inclination/direction, etc.). |

|

grasping object by 3D |

LIDAR sensor |

Sensor grasping surrounding objects in 3D by infrared ray. |

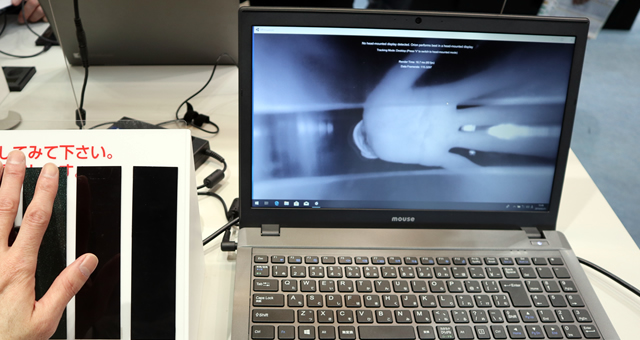

- Example of motion sensor achieving both pearl color decoration to a sensor port and sensing accuracy

-

2. Introduction of new designs utilizing light

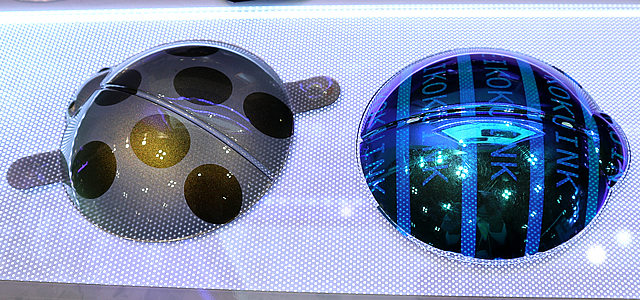

1. Design utilizing concealing print

Ink for sensor (IR transmittable ink) mentioned above can apply to “concealing print” which realizes a completely different design between normal time and when backlight is illuminated, by adjusting wavelength of transmittable light in the visible light region. Ink for sensor can also be utilized in security areas such as forgery prevention other than decoration purposes.

- Molding with various decorations (they cannot be distinguished existence of concealing print)

-

- Completely different design than usual realized by backlight

-

- Example of moldings with concealing print

-

- Design when backlight is illuminated

-

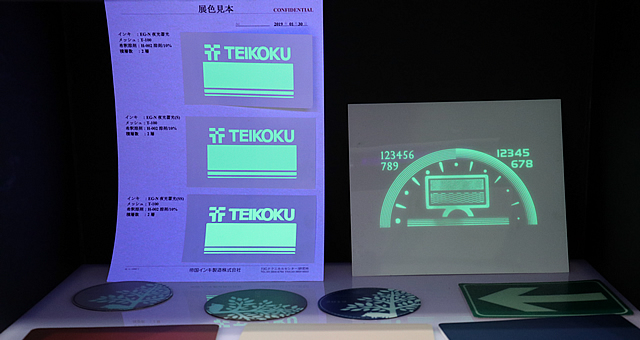

2. Design utilized phosphorescent function

Phosphorescent ink is the ink that has properties which absorb and accumulate the energy of light beam from sunlight and electric light, etc. and then release energy gradually and emit light. This ink can repeat the process of absorption, accumulation, and emission over and over. It is also possible to realize new design and apply to safety and power saving measures.

- Example of illuminating phosphorescent ink by using black light

-

3. Introduction of realization of high grade image by highly accurate printing and High Definition Ink System

1. Provide high grade image by fine printability

High Definition Ink (high quality and high definition screen ink) makes stable printing possible even fine lines of L/S (line and space) 100µm with sagging width of one side between 5 to 8µm. (Compared to High Definition Ink, conventional screen printing was several times of L/S, several hundred of µm, and sagging width 20µm or more.) Highly fine printability of this High Definition Ink enables luxurious feeling design that has not ever been seen.

- Example of design utilizing fine printability printed on smartphone glasses

-

- Example of fine printability of High Definition Ink applicable to adding high grade image

-

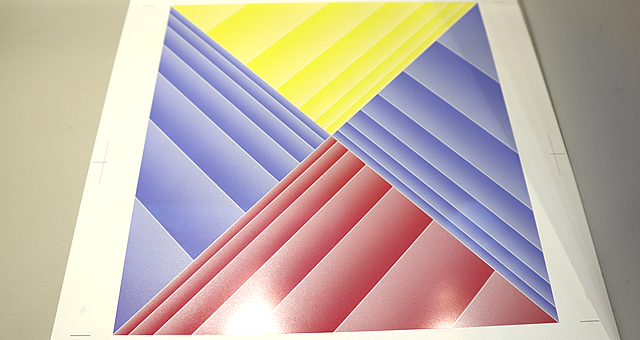

2. Add high grade image by beautiful solid print and gradation

High Definition Ink also achieves gradation with a high resolution by means of beautiful solid print without color unevenness and dot diameter of 100µm or less.

- Example of accurate gradation printing with dot diameter 100µm or less

-

- Example of expressing material feeling never seen before by means of combining unique color hue with solid printing and gradation

-

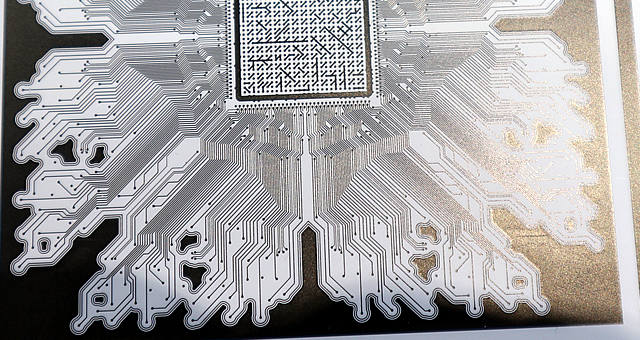

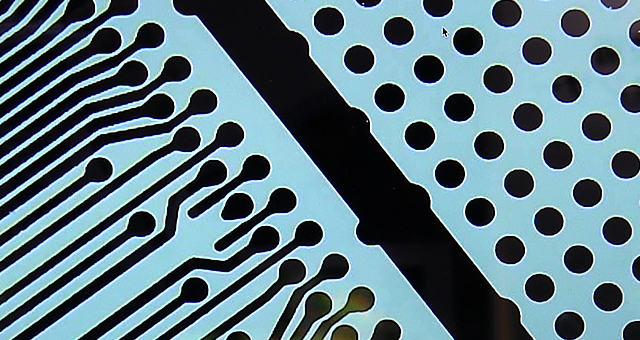

3. Add high grade image by means of excellent printing accuracy

Conventional screen printing sometimes generates concavo-convex called saw edge on a boundary line of the print. However, High Definition Ink makes smooth boundary lines possible without concavo-convex. This excellent printing accuracy enables to decorate the products whose quality requirement is strict.

- Check circuit board design printed by High Definition Ink with a microscope

-

- Example of 100µm width line and 250µm dot diameter printed with a high accuracy

-

4. Introduction of adding high grade image by means of reproducing real material feeling

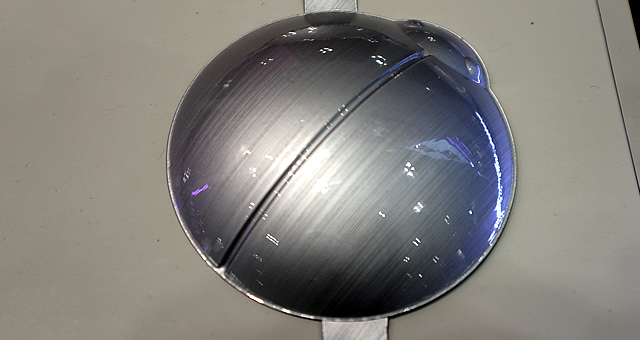

1. Realization of gloss and material feeling like a real metal

Metallic design with a high grade image without plating process is possible by combining mirror ink and molding. Mirror ink has huge advantages in environment and costs because substance of concern is not used in unlike metal plating.

- Example of a decoration combining mirror ink and molding as substitute for metal plating

-

- Example of a molded sheet on which mirror ink is printed by a roll coater. This achieves both high grade metallic image and cost reduction.

-

2. Realization of black like lacquered black (piano black)

Lacquered elegant black, which called jet black or piano black, is an essential color to add high grade image. Utilizing this jet black enables to add unique high grade image to moldings and glasses.

- Example of molded sheet on which jet black is printed by a roll coater. This achieves both high grade image of jet black and cost reduction.

-

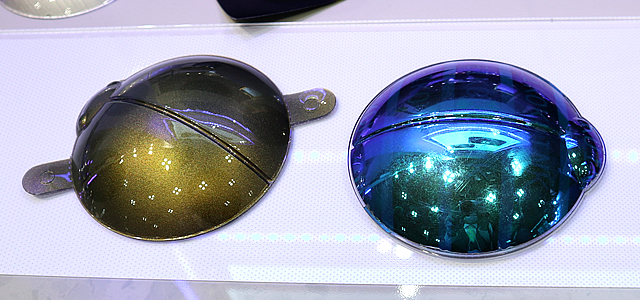

3. Realization of smooth color like pearls and beautiful gloss

Pearl and STELLA ink, with their reflected lights interfering with each other like natural pearls, realize unique high grade design that changes its color depending on the viewing angle.

- Example of a molded sheet on which STELLA ink is printed by a roll coater

-

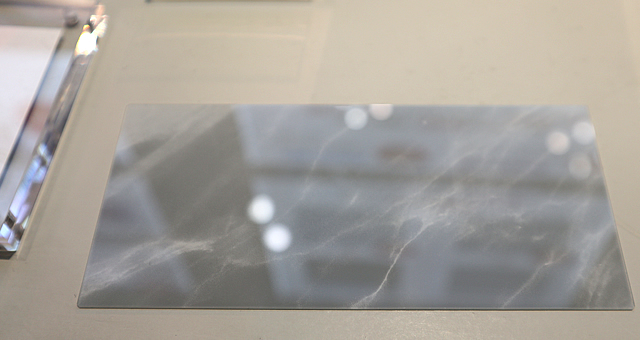

4. Realization of high grade feeling genuine article has

High grade feeling genuine article has can be reproduced by highly accurate printing of High Definition Ink mentioned above.

- Example of realization of genuine material feeling by reproducing fine patterns of marble accurately

-

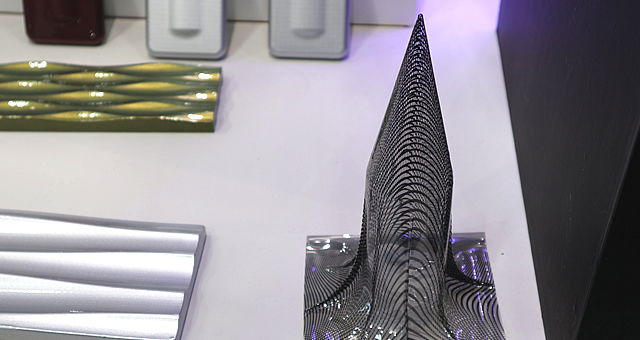

5. Introduction of decoration to 3D (three-dimensional object) and improvement of designability by substitute for painting

1. Realization of luxurious feeling design by Film Insert Molding (FIM)

Film Insert Molding (FIM), also called In-Mold Decoration (IMD), is the method that inserts a screen printed film into a mold and decorates molded article by integral molding.

Free and luxurious feeling design, which many colors are utilized for, can be applied to 3D objects because this method is decoration by printing different from painting. Compared to painting, this method is also excellent in environment and costs such as lower VOC emission and no special facility necessary, etc.

-

- Example of combining fine lines of 100µm level and molding

-

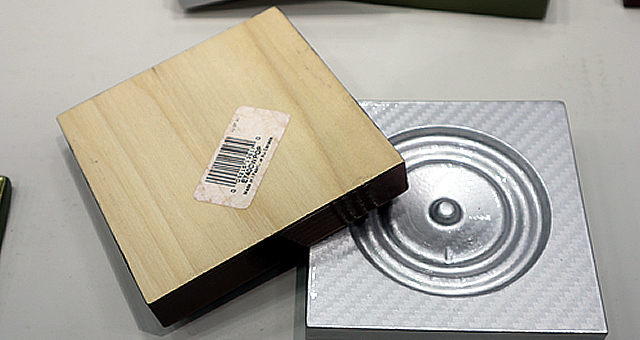

2. Decorate 3D objects by TOM molding

TOM (Three Dimension Overlay Method) molding is the method that a decorative film, which was heated and plasticized, is laminated to decorate directly a 3D object. It can decorate 3D objects of many kinds of materials such as metal, resin and wood, etc.

- Example of 3D wood object with painting-like decoration

-

-

3. PAD printing printable directly on 3D objects

PAD printing is the method that transfers ink to a silicone pad and imprints ink on the printed material like a stamp. Ink can be printed directly on a 3D object because a pad deforms itself in accordance with the printing surface.

- Example of 3D animal head figurine (metallic material) decorated directly by PAD printing

-

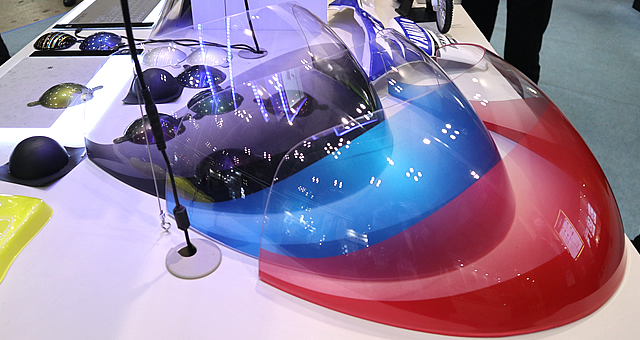

4. Decorate moldings by pneumatic forming and vacuum forming

Decoration of moldings by pneumatic forming and vacuum forming is the method of forming a sheet which is decorated by screen printing. Unlike film insert molding mentioned above, this method has no injection molding process.

- Example of applying gradation printing to windshield cowl of motorcycle

-

6. Introduction of functional clear which gives various resistance and functionalities

1. Functional clear which gives excellent scratch resistance

Functional clear is clear ink that adds various resistance such as scratch resistance and weather resistance, etc. and adds functionalities such as optical properties and slip resistance. For instance, by applying clear with excellent scratch resistance to home appliances and car interior, products can be protected from scratches and can be kept new-looking.

- Example of self-restoring clear that restores even metal brush scratches (left side is gloss and right side is matte)

-

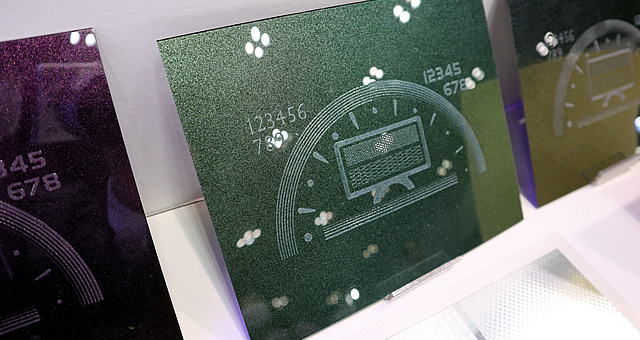

2. Realize both visibility and designability by clear ink with excellent adjustment of optical properties

Clear with excellent optical properties is clear ink that is designed to improve product designability and visibility by freely adjusting characteristic values related to light transmission and reflection. For instance, clear can be applied to car meters, etc. that require visibility.

- Comparative example of visibility of car meters whose optical properties are adjusted by clear (matte is left side and gloss is right side)

-

3. Improvement of designability by applying functions of optical properties and thick layer

By combining optical properties of clear and thick layer printing which gives three-dimensional decoration, the functions such as three-dimensional emphasis, touch feeling, and visibility, etc., are added to the products and that can realize design with high appeal effect.

- Example of the design provided by UV thick layer clear on the sheet printed with pearl color of high grade image

-

- Related technical information

-

- Ink for sensor

- Introduction of GLS-HF ink(2)

- Introduction of IR transmittable ink (IR Transmitting Ink) and concealed printing

- Introduction of Luminova Phosphorescent Ink

- Introduction of High-Definition Ink (high-quality, high-definition screen ink)

- Introduction of 7 benefits

- Introduction of High Quality and High Definition Screen Printing Ink

- MIR-51000 Mirror Silver

- Introduction of functional Black ink

- High Definition Ink System for Molding

- Technology lecture for FIM/IMD 1st session: Explanation of the merit and 3 process.

- Introduction of FLG-HF G05

- Introduction of UV TAF (A) Clear

- Introduction of MIX-HF ink(3)

- Introduction of VK Ink Series

- Related event information

Please feel free to contact us about the inks, methods, and trial products we have introduced.