Past events

Exhibition Report of 30th FINETECH JAPAN

Event outline

The 30th Finetech Japan is a business exhibition where electronic displays, their manufacturing equipment, and material technology are exhibited all together. Teikoku exhibited the latest inks and printing technologies such as concealing printing making design appear when it is illuminated optically, ink for sensor (IR transmittable inks), ink for electromagnetic wave shield non-conductive black ink, High Definition ink (high quality, high definition screen ink), etc.

- Period

- December 2 – December 4, 2020

- Venue

- Makuhari Messe, Japan

- Official HP

- https://www.ftj.jp/en-gb.html

List of Exhibits

- 1. Introduction of concealing printing (hidden printing)

- 2. Introduction of application of concealing printing utilizing LED light source

- 3. Introduction of ink for sensors (IR transmittable ink) contributing to self-driving

- 4. Introduction of high transparency IR transmittable ink for high performance sensors

- 5. Introduction of electromagnetic wave shielding ink

- 6. Introduction of non-conductive ink supporting electrostatic discharge

- 7. Introduction of High Definition Ink (high quality and high definition screen ink)

- 8. Introduction of FIM technology decorating molded display (curved surface display) beautifully

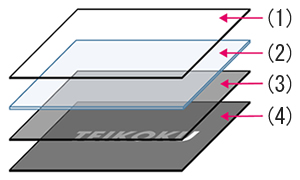

1. What is concealing printing (hidden printing) ?

Concealing printing is a printing expression that a design appears when a backlight illuminates it. By multi-layer printing of matt clear, transparent color and outline pattern makes concealing printing possible. Dynamic designs which express surprises can be possible by this concealing printing.

(1) Front: Matt clear, (2) PC substrate, (3) Back 1st layer: Transparent color, (4) Back 2nd layer: Outline pattern

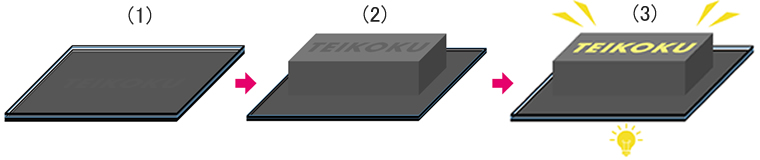

(1) Printing, (2) Molding, (3) Backlight illumination (Characters appear! (Dynamic design expresses surprises))

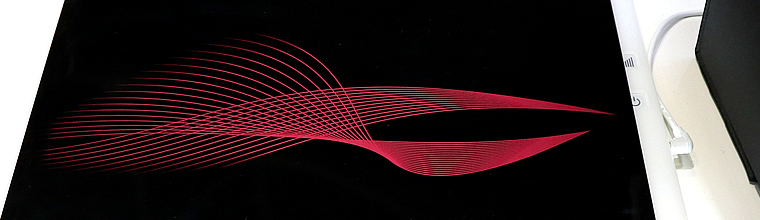

2. Concealing printing making free and beautiful design possible

Concealing printing enables you to set outline patterns and transparent color freely. Therefore, by using light, it makes a beautiful design you have never seen hidden and a design with a high presentation effect possible.

Express rich and beautiful black color (without backlight)

Beautiful design with light and fine lines (when backlight is illuminated)

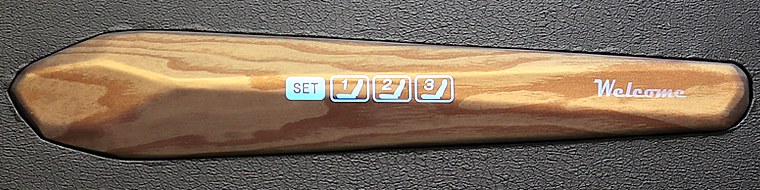

3. Realize both elaborate printing expression such as woody texture and concealing printing

Concealing printing can be also applied to elaborate printing expression such as wood pattern. Therefore, you can newly add functions such as dynamic presentation and status display with light by concealing printing to the part where elaborate design was already decorated.

Elaborate wood pattern as if it were real (without backlight)

Clear display as if it were originally on the woody texture (when backlight is illuminated)

Presented by Nakanuma Art Screen Co., Ltd.

2. Introduction of application of concealing printing utilizing LED light source

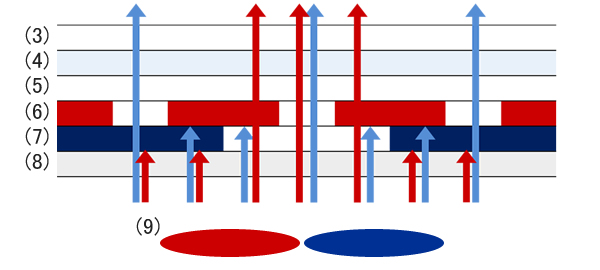

1. What is the mechanism of dynamical image switching by combining LED light and transparent color ?

By applying concealing printing, it is possible to switch not only colors but also patterns by changing the irradiation light (light from LED light sources with the same wavelength).

For example, by combining LED light source whose wavelength of red (wavelength: 580 nm to 780 nm) and blue (wavelength: 435 nm to 580 nm) was aligned and the ink only whose wavelength light is transmitted, it is possible to switch dynamic image by selecting LED light source (please refer to the figure below).

(1) Image when LED red was illuminated, (2) Image when LED blue was illuminated

Image of combinations that only red light transmitted, only blue light transmitted, both lights transmitted, and both lights did not transmit

(3) Substrate, (4) Transparent ink, (5) Smoke ink, (6) Ink transmitting only red wavelength, (7) Ink transmitting only blue wavelength, (8) Diffusion ink, (9) Two LED light sources of red and blue

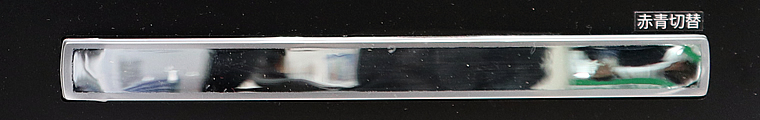

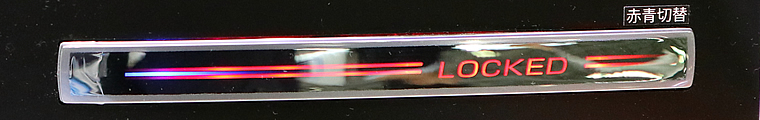

2. Switching image on the same part by LED light sources of red and blue

By using the above mechanism, it is possible to switch images freely on the same part by using red and blue LED light sources separately. The following is an example of two types of designs when red light was irradiated and when blue light was irradiated, which were applied on one part.

Without backlight irradiation (Beautiful metal color was applied)

When red light was irradiated (blue light began irradiating from the left side. The part where light was transmitted is different from red light.)

When blue light was irradiated (“LOCKED” in red light was changed to “UN LOCKED” in blue light.)

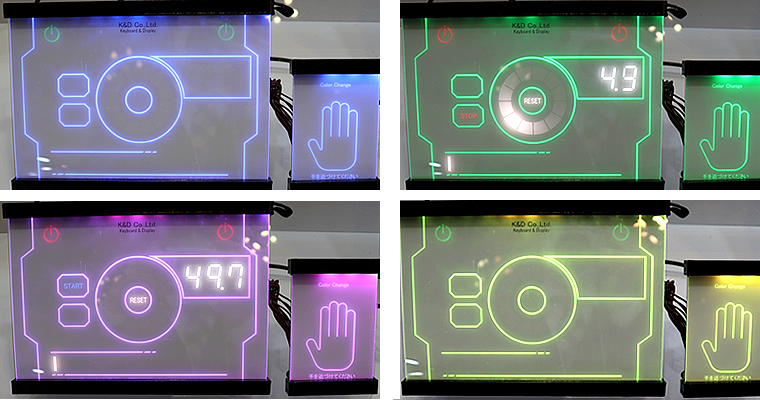

3. Multicolored concealing printing with variations of LED light sources and transparent colors

By elaborating combination of LED light source colors and transparent colors, and design to draw, it is possible to create a colorful and dynamic design.

Presented by K&D Co., Ltd.

3. Introduction of ink for sensors (IR transmittable ink) contributing to self-driving

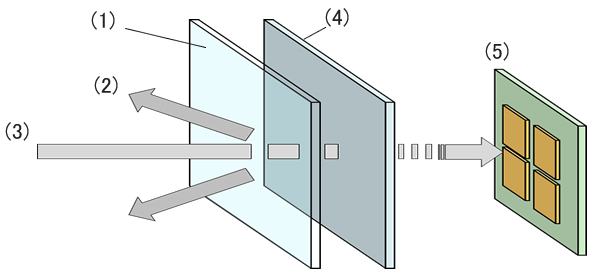

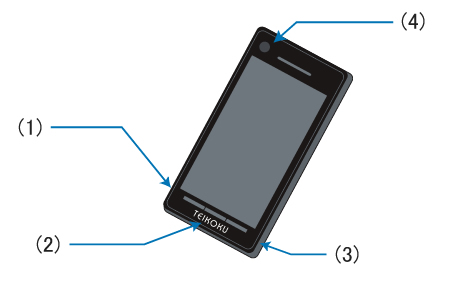

1. What is sensor ink (infrared transmittable inks, IR transmittable inks) ?

Sensor ink is a decorative ink which has light transmission function of light (infrared rays) a sensor should detect. By utilizing this ink, it is possible to apply decoration on the sensor receiving port in the same way as surrounding. In short, sensor function and seamless design are possible at the same time.

Sensor ink contributes to improving functions such as prevention of sensor malfunction because it also prevents unintentional transmission of ultraviolet rays or visible light and diffused reflection, etc.

(1) Product body (PC, PET film, glass), (2) Visible light, ultraviolet rays causing malfunction (3) Light of wavelength to be detected (Infrared), (4) Sensor ink, (5) Sensor module

2. Ink for sensor indispensable for safe and self-driving technology

In order to improve the safety of vehicles and realize self-driving, it is necessary to equip many sensors in a vehicle. For example, millimeter wave radar reading the distance between an object and a person, a motion sensor grasping those movements, and LiDAR sensors grasping surrounding conditions three-dimensionally including all of them.

Sensor inks contribute to improvement of both decoration and functionality of various sensors which are indispensable for safety improvement and self-driving.

| Sensing object | Sensor | Detail |

|---|---|---|

|

“Distance” to object |

Millimeter wave radar |

Radar using millimeter wave band (wave length 1 – 10mm = frequency 30 – 300GHz) |

|

“Motion” of object and people |

Motion sensor |

|

|

Grasp objects in 3D |

LiDAR sensor |

Sensor that can grasp surrounding objects three dimensionally with infrared. |

Sensor inks available in various colors including pearl color

4. Introduction of high transparency IR transmittable ink for high performance sensors

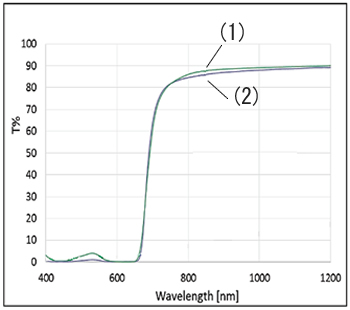

1. What is high transparency IR transmittable ink ?

Compared to conventional IR transmittable ink, high transparency IR transmittable ink is an ink which improves transmitted light volume and reduces diffusibility of light which causes malfunctions. For high performance sensor and realization of seamless design, it can make the best use of its ability.

Comparison between high transparency IR transmittable ink and conventional IR transmittable ink

|

All rays transmittance |

Diffusibility (diffuse transmittance) |

|

|

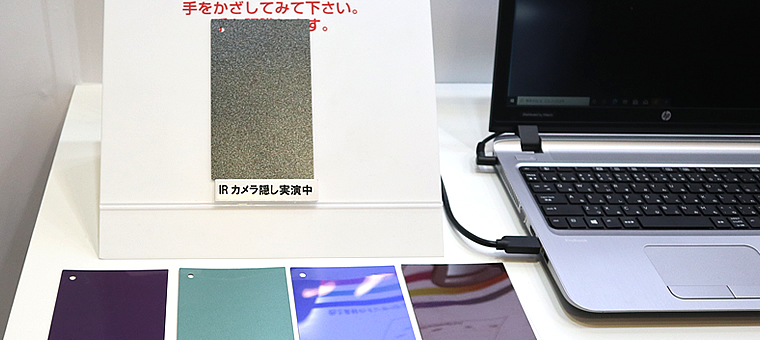

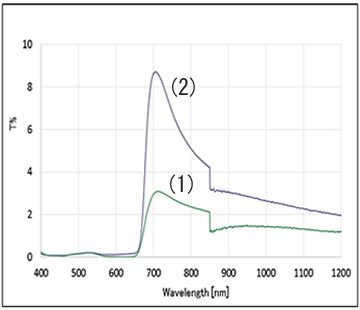

2. Image comparison between high transparency IR transmittable ink and conventional IR transmittable ink

The following is an image comparison where high transparency IR transmittable ink and conventional IR transmittable ink were applied to the actual motion sensor. High transparency IR transmittable ink (right figure) detects the boundary area of the hand more clearly than that of conventional IR transmittable ink (left figure).

5. Introduction of electromagnetic wave shielding ink

1. What is electromagnetic wave shielding ink ?

Electromagnetic wave shielding ink is a kind of conductive ink. When the electromagnetic wave is incident on the printed ink layer with conductivity, over current is generated, and reflects the electromagnetic wave. The higher conductivity the ink has, the higher shielding performance it will have.

2. Merits of printing method

Compared to electromagnetic wave shielding films, electromagnetic wave shielding ink is an inexpensive method because it does not require the process of attaching. In addition, customizations such as coexistence with light transmission by printing only necessary area and mesh printing, which were difficult with other methods can be realized at low cost. Moreover, it has excellent resistance to humidity compared to other methods using metal.

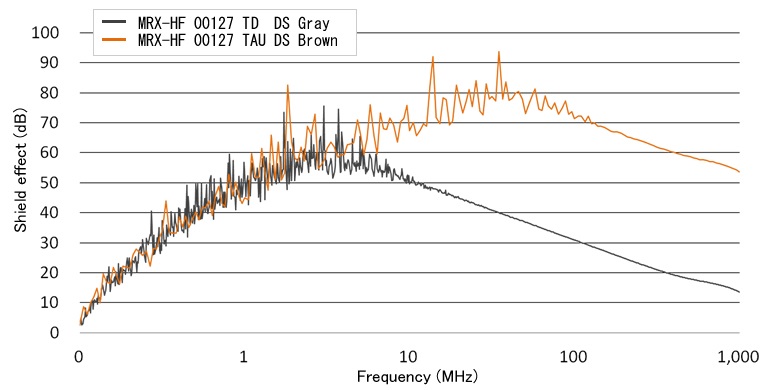

3. Performance of electromagnetic wave shield ink

| Ink name | Surface Resistance Ω |

0.3 – 3 MHz |

3 – 30 MHz |

30 – 300 MHz |

0.3 – 1 GHz |

|---|---|---|---|---|---|

|

MRX-HF 00127 TD DS Gray |

100Ω |

30 – 60dB |

40 – 60dB |

20 – 40dB |

18 – 22dB |

|

MRX-HF 00127 TAU DS Brown |

1Ω |

40 – 65dB |

65 – 80dB |

65 – 80dB |

50 – 60dB |

Shielding performance value of electromagnetic wave shield ink

Test conditions: ink layer thickness 15 µm, test substrate PC, drying condition 80°C for 30 minutes

Printing conditions:

Gray T-250 Mesh, Z-004 Solvent 5%, 210 Catalyst 5%

Brown T-250 Mesh, SM-800 Additive 10%, 210 Catalyst 5%

Printing example of electromagnetic wave shield ink (MRX-HF 00127 TAU DS Brown)

Electromagnetic wave shield ink for glass (MRX-HF 00127 TAU DS Black)

6. Introduction of non-conductive ink supporting electrostatic discharge

1. What is non-conductive black and non-conductive metallic ink ?

Conventional black ink and metallic ink used conductive materials such as carbon and metallic, etc. Therefore, when they were used in electronic devices, they had risks such as sparks or radio disturbance of electric circuit because static electricity conducted the printed ink layer. However, this non-conductive black ink and non-conductive metallic ink can be safely used in electronic devices because they form printed ink layers which have high electrical resistance values.

| Ink name | Electric resistance value of conventional ink | Electric resistance value of non-conductive ink |

|---|---|---|

|

Black Ink |

About 104~5Ω |

1010Ω or more |

|

Metalic Ink |

About 105~10Ω |

1010Ω or more |

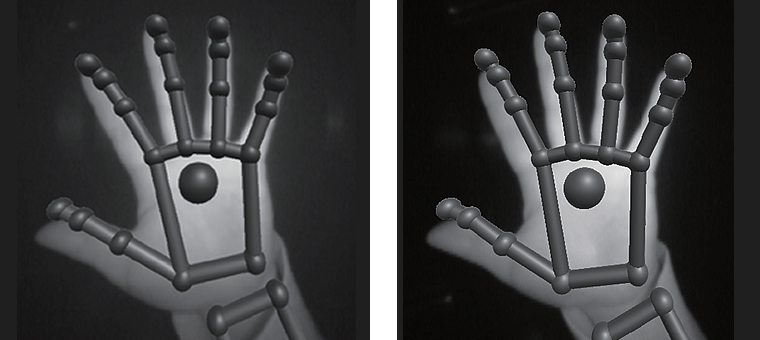

2. Application of non-conductive black and non-conductive metallic ink to electronic devices

Non-conductive black ink is used for the frames of displays as it has both high concealment and non-conductivity. Non-conductive metallic ink is also used when you add a high class feeling metallic design to electronic devices.

(1) Frame printing with electrostatic discharge (non-conductive black ink), (2) Logo printing (non-conductive metallic, mirror ink), (3) Frame printing (high concealment 679 White, 979 Black), (4) Decoration to sensor part (sensor ink)

Example of applying non-conductive black ink and non-conductive metallic ink to the display frame

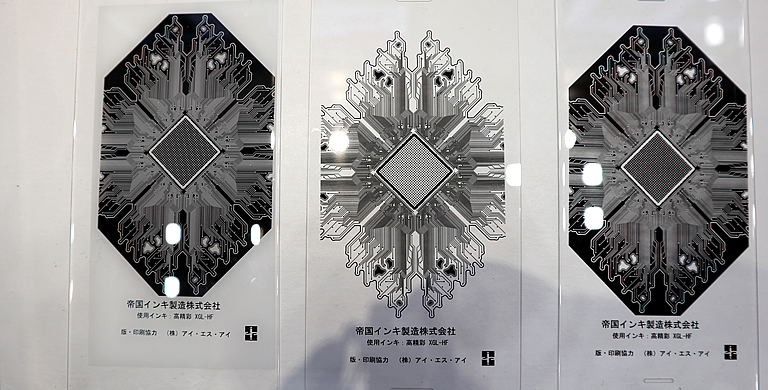

7. Introduction of High Definition Ink (high quality and high definition screen ink)

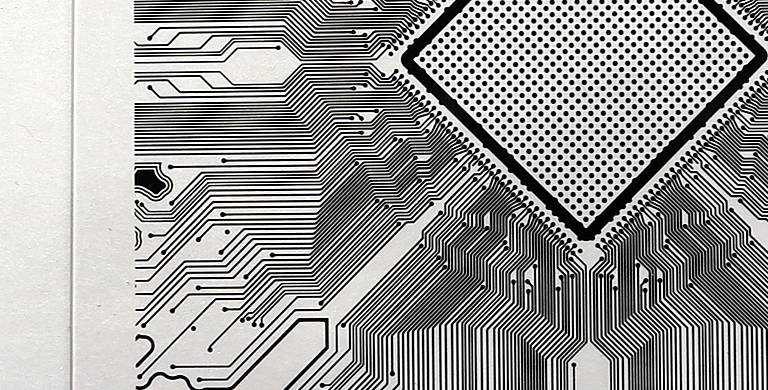

1. What is High Definition Ink (high quality and high definition screen ink) ?

High Definition Ink is a high quality and high definition screen ink which enables high quality printing of fine lines with L/S 100µm, gradation with 100µm dot diameter, and thick solid, which were difficult with conventional screen inks. The following is a comparison of print quality between High Definition ink and conventional ink.

| Benefit of printing quality | Conventional Ink | High Definition Ink |

|---|---|---|

|

Benefit 1: |

L/S (line and space) 100µm fine line is printed with least 20µm sagging width on one side. Stable printing is difficult even with several hundred µm dot diameter. |

L/S (line and space) 100µm fine line can be printed stably with sagging width of 5 to 8µm on one side. Dot diameter 100µm can be printed stably. |

|

Benefit 2: |

It is necessary to print separately with a different mesh and printing condition |

Solid print, fine lines and gradation can be printed on one stencil. |

|

Benefit 3: |

Saw edge occurs when printing straight line and outline printing of a perfect circle |

Perfect straight line and outline printing of a perfect circle are possible with less than 10µm saw edge. |

2. Express high class feeling with High Definition ink (high quality and high definition screen ink)

Thanks to high quality printing High Definition ink has, delicate design using 100µm fine lines and high class feeling design with rich solid and high resolution gradation, etc. are possible.

Example of high class feeling design making the best use of fine lines and dots by High Definition ink

Even 100µm line and space, and 250µm diameter dots are printed with high quality.

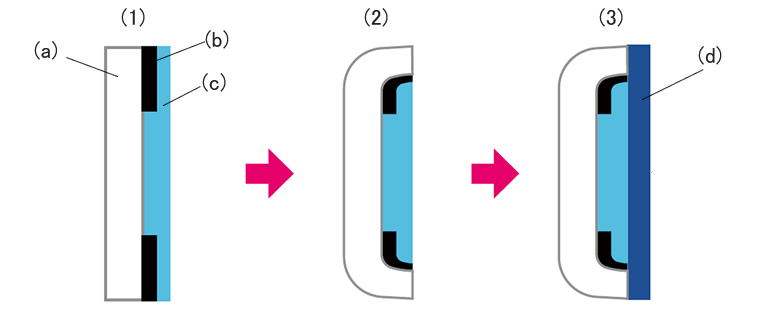

8. Introduction of FIM technology decorating molded display (curved surface display) beautifully

1. What is FIM (Film Insert Molding) ?

FIM (Film Insert Molding) is a method which decorates the molded article by molding thermoplastic resin on which design was already printed and resin molding material integrally. Compared to painting, this method has excellent features such as simple and low cost, high flexibility of design (multicolor and fine lines are possible).

(1) Screen printing, (2) Forming, (3) Injection

(a) Thermoplastic resin film, (b) Printed ink layer, (c) Binder layer, (d) Molding resin

2. Decoration to the frame of a molded display (curved surface display) by FIM technology

Even the frame of the molded display using a special acrylic sheet can be decorated beautifully by FIM (Film Insert Molding) technology.

Adding mark to the frame is easy because it is decorated by printing

Even decorating to the molded display with complicated shape is possible

- Related technical information

-

- Introduction of GLS-HF ink(2)

- Introduction of IR transmittable ink (IR Transmitting Ink) and concealed printing

- Ink for sensor

- Electromagnetic wave shielding ink

- Introduction of Non-Conductive Black ink

- Introduction of non-conductive Metallic ink

- Introduction of functional Black ink

- High Definition Ink System for Molding

- Introduction of 7 benefits

- Introduction of High Quality and High Definition Screen Printing Ink

- Technology lecture for FIM/IMD 1st session: Explanation of the merit and 3 process.

- Introduction of High-Definition Ink (high-quality, high-definition screen ink)

- Related event information

Please feel free to contact us about the inks, methods, and trial products we have introduced.