Past events

Exhibition Report of Smart Sensing 2022

Event outline

Smart Sensing 2022 is a technology exhibition based on the concept of creating a new world with sensing technology. We exhibited our latest printing technology that combines sensor-compatible ink (IR transmittable ink) and non-contact sensors, which contributes to improved sensor performance and design, as well as cost reduction.

- Period

- June 15 - June 17, 2022

- Venue

- Tokyo Big site

- Official HP

- https://www.smartsensingexpo.com/index.html

List of Exhibits

- 1. Sensor ink contributing to self-driving and safe driving

- 2.Dead front printing (concealing printing)

- 3. Application of Dead front printing. Introducing “Changing”, changing the image with light source

- 4. Decorating technologies for non-contact switches applied in a variety of fields

- 5.”Shy Tech” technology

- 6.Inks for electromagnetic wave shielding that contribute to product weight reduction

1. Sensor ink contributing to self-driving and safe driving

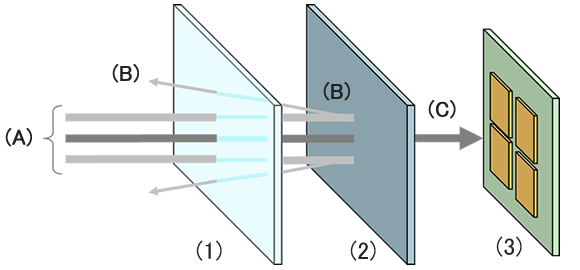

1. What is sensor ink (IR transmittable ink) ?

Sensor ink, also called IR transmittable ink, is a decorative ink which blockes visible light and UV rays causing sensor malfunction and transmits only infrared rays. By replacing the IR transmissive film that is used for an IR transmissive part with sensor ink, decorating IR transmissive part is possible. Moreover, sensor ink contributes to cost reduction because printing processes are fewer than film attaching processes.

(A)IR and visible light and UV rays causing malfunctions,

(B)Visible light and UV rays blocked (absorbed or reflected) by ink for sensor,

(C)Transmitted IR

(1)Product body (PC, PET film, glass),

(2)Sensor ink,

(3)Sensor module

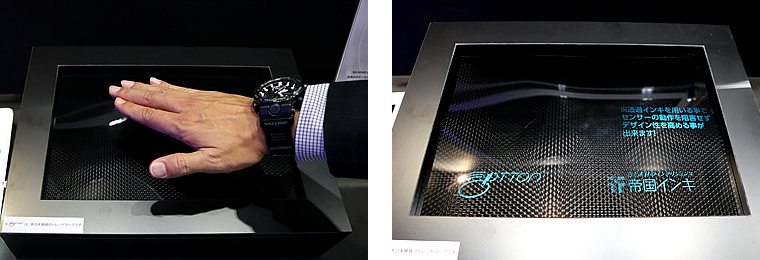

2. Demonstration example of transparency of ink for sensor by an infrared camera

High transparency IR Transmittable Ink is effective for blindfolding the lens portion of infrared cameras for security purposes, which are already in practical use.

Since the transparency of ink for sensor is higher than that of ordinary IR transmittable inks, clear images can be recognized.

For future market development, it can be considered for components that require high-precision image recognition, such as camera lens blindfolds for driver status monitors that check the driver’s movements, and LiDAR sensors.

The left side of the display is the LiDAR sensor and the right side is the IR camera, which clearly shows the hand when a printed material with IR transmittable ink is held in front of the hand.

2.Dead front printing (concealing printing)

1. What is dead front printing (concealing printing) ?

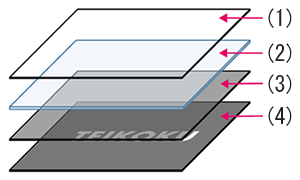

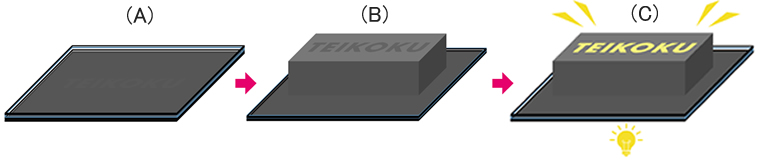

Dead front printing is a printing expression that a design appears when backlight is illuminated. Dead front printing can be produced by multi-layer printing of matt clear, transparent color and a die-cut pattern. Dynamic designs creating surprises are possible by this dead front printing (concealing printing).

(1) Front: Matt clear, (2) PC substrate, (3) Back 1st layer: Transparent color, (4) Back 2nd layer: Outline pattern

(A) Printing, (B) Molding, (C) Backlight illumination (Characters appear! (Dynamic design creates surprises))

2. Dead front printng for various base design

Dead front printing allows a variety of colors to be selected for the base and transparency colors. For blackout (black base), piano black (jet black), matte black, etc. can be selected. Dead front printing on parts with complex designs can also be vividly expressed without being blended in with the base design when illuminated by backlight.

*Examples of Dead front printing on piano black (jet black).

*Different colors are expressed on the left and right (under backlight illumination).

*Example of Dead front printing on the complex design.

*Dead front design is expressed without being affected by the base design. (under backlight illumination)

Exhibition Cooperation: Nakanuma Art Screen Co., Ltd.

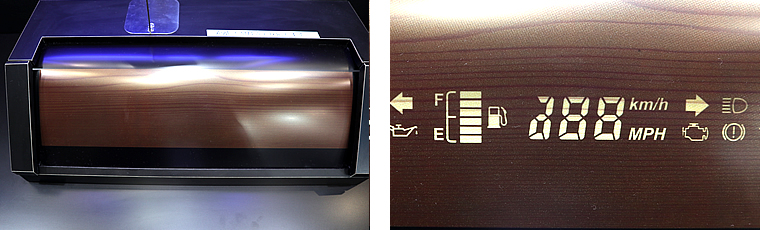

3. Application of Dead front printing. Introducing “Changing”, changing the image with light source

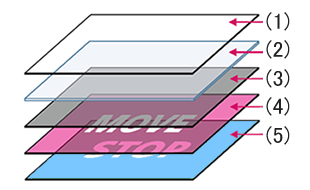

1. How “changing” works: Dead front printing of two images on a single part

By applying Dead front printing, it is possible to apply multiple stealth images to a single part. For example, by preparing two die-cut patterns, one with red light-blocking ink and the other with blue light-blocking ink, “changing”, between red and blue light image becomes possible.

(1) Surface: Matt clear, (2) PC substrate, (3) Back 1st layer: Transparent color

(4) Back 2nd layer: Red outline pattern, (5) Back 3rd layer: Blue outline pattern

The image can be switched by changing the red light to blue light.

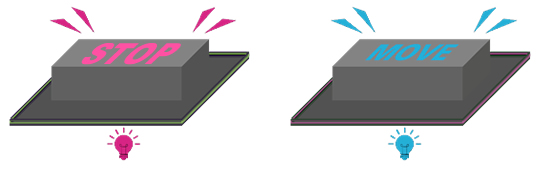

2. Example of changing red to blue of large molded objects

Dead front printing also can be applied to large molded objects, as shown below.

Large molded object that resembles the rear of an automobile.

Exhibition Cooperation : Asano Laboratories Co., Ltd.

The word “STOP” is displayed when red light source is irradiated.

“MOVE” is displayed when blue light source is irradiated.

Irradiation of red and blue light source (images hidden by changing)

4. Decorating technologies for non-contact switches applied in a variety of fields

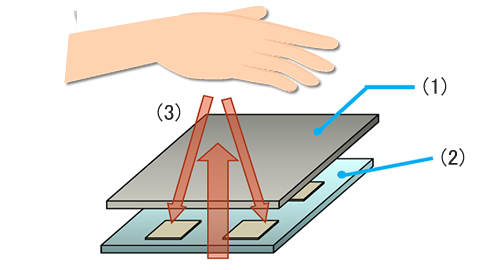

1. What is a non-contact switch ?

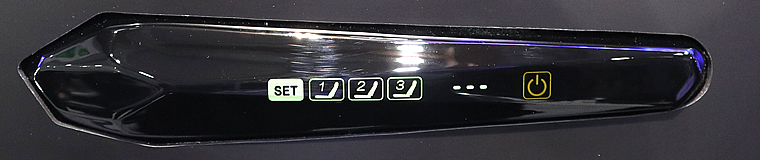

A non-contact switch can be turned on and off without touching it by a built-in infrared sensor detecting a hand held. By printing sensor inks on the infrared light emitting/receiving port, it is possible to create a design that does not make the user aware of the built-in sensor.

(1) Cover glass on which sensor ink was printed

(2) Sensor body (IC chip)

(3) Infrared rays sensor receives and emits

2. Sensor ink that expands the possibilities of non-contact switches

Sensor inks allow adjustment of the transmission wavelength and degree of transmission to match the characteristics of the sensor that the non-contact switch is incorporated with. In addition, sensor inks provide more freedom in decoration on non-contact switches, making it possible to apply them in a variety of fields.

| Direction of decoration | What you want to achieve | What sensor ink can support |

|---|---|---|

| Show | To stand out as non-contact switch for infectious disease control | Free design of switches without physical limitations |

| Hide | Detect only specific conditions without making people aware of the sensor. |

Allow seamless design to hide the sensor (Application for design improvement and security measures) Capable of detecting and responding to the specific situation without the user being aware of it. (Application for power saving to control power supply depending on the situation. Details to follow,) |

| Hide + Show | Hide the information when it’s not necessary and provide it when necessary | Combination with Dead front printing can provide “necessary information when needed”. (Shy Tech), (details to follow) |

3. Application to Non-contact buttons

Products that are touched by an unspecified number of people are beginning to be non-contact. By combining distance-measuring sensor and IR Transmittable ink, it is possible to apply this technology to non-contact buttons.

IR transmittable ink is ideal for components where the sensor component should not be noticeable, but its functionality should not be reduced.

Exhibition Cooperation: Elevisor Japan Inc., TOA Electronics, Inc.

5.”Shy Tech” technology

1. What is Shy Tech ?

Shy Tech is a technology that eliminates the need for constant display of gauges and indicators, and provides the necessary information when it is needed. This technology makes it possible to use simpler and more beautiful designs for automobile driver seats and interior parts, which tend to be overloaded with information, without sacrificing convenience.

2. Realizing Shy Tech with non-contact switches and Dead front printing

In order to realize Shy Tech’s goal of “providing necessary information when necessary,” non-contact switches using sensor-compatible ink and Dead front printing will be effective technologies. For example, an area that was just a decorative surface can be converted into an area that provides information that was hidden by Dead front printing by using a non-contact switch to detect the need for information.

A non-contact switch detects the need for information (left photo), and Dead front printing provides the necessary information (right photo).

Exhibition Cooperation: Nisshinbo Micro Devices Inc.

3. What is Smart Surface ?

Smart Surface means literally a smart surface which indicates a surface material with multiple functions and high performance. We have developed the meaning of “Shy Tech” and consider it to be a technology that supports both “functional smartness” that displays the necessary information when it is needed and “design smartness” related to decoration.

Our High-Definition Ink contributes to the realization of this Smart Surface. In addition to the ability to reproduce materials with a sense of luxury, such as wood grain and marble, High-Definition Inks also demonstrate its power as high-opacity black inks with the fine printability and high opacity required for high-quality Dead front printing.

Real wood like design with High-Definition Inks (left photo) and information displayed with Dead front printing.

Exhibition Cooperation: KODENSHI TK CORP., NS Advantech Co.,Ltd.

6.Inks for electromagnetic wave shielding that contribute to product weight reduction

1. What is electromagnetic wave shielding ink ?

Electromagnetic wave shielding ink is a kind of conductive ink which makes conductive printed ink layer block (shield) intrusion or leakage of electromagnetic wave. Compared to other shielding materials such as metal foil, it is lighter, thinner, and has superior functionality such as high moisture resistance.

The following is an example that the printed material using electromagnetic wave shielding ink shields electromagnetic waves (radiation electric field was measured) radiating from the PC display. The radiation electric field is shielded from measured value in normal time (128 V/m) (left photo) to unmeasurable value (0 V/m) (right photo).

(Exhibition Report on 13th Automotive World)

2. Advantages of electromagnetic wave shielding inks

Electromagnetic waves shielding by printing is a superior method in resistance, lighter and thinner, and process reduction compared with other methods using metal foil or the like.

| Excellent features | Details |

|---|---|

| High moisture resistance, lightweight and thin |

|

| Inexpensive and flexible screen printing |

|

| Achieve both decoration and other functions |

|

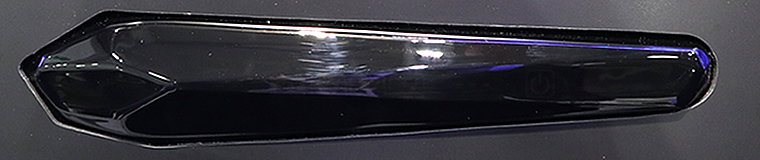

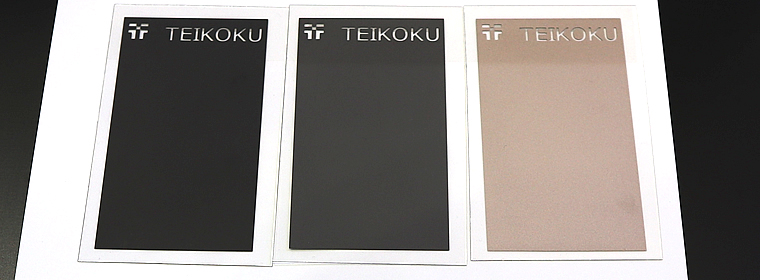

3. Printing example of electromagnetic wave shielding inks

The followings are printing samples of MRX-HF Conductive Black, Gray, and Brown ink. Electromagnetic wave shielding inks can do both shielding electromagnetic wave and decorating in a single printing process. In case of decorating other than standard colors, it is possible to express designs freely by overprint with regular inks.

Printing example of MRX-HF Conductive Black, Gray, and Brown ink.

Printing conditions:

Black・Gray T-250 Mesh, Z-004 Solvent 5%, 210 Catalyst 5%

Brown T-250 Mesh, SM-800 Additive 10%, 210 Catalyst 5%

- Related technical information

- Related event information

- Related ink

Please feel free to contact us about the inks, methods, and trial products we have introduced.