Trouble shooing in MIR ink printing

Q&A on Mirror Ink

Many kinds of printed matters, which were formed in 3-D forms such as dummy bottles for automatic vending machines, are widely used in the market.

We are now introducing our new product, "FOM Ink", which is quite suitable to vacuum forming. It has an excellent adhesion to Polycarbonate substrate, excellent heat resistance, excellent elongation of the ink film and other good resistances.

Please test the new ink for your prints, which are to be post-formed by various forming methods such as vacuum forming, pressure forming, etcB.

Q1. We wish to have a high opaque print with Mirror Ink. How can we get it?

A1. Please use squeegee of 70-degree hardness, and rather higher print pressure.

We got some questions that it is rather difficult to get good opacity as in our print samples.

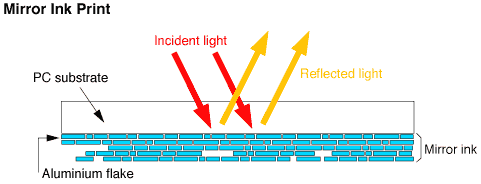

To get good opacity, changing the hardness of squeegee is often effective. As the Mirror ink has less resin in it, it is not easy to get good transfer from the stencil to substrates. Changing the hardness of squeegee may help to get good transfer.

We recommend following conditions.

| Squeegee hardness | 70-degree |

| Print pressure | rather high |

| Doctor pressure | rather high |

Q2. Is over-printing necessary?

A2. Over-printing is a must.

Over-printing is needed not only to increase the scratch resistance of the mirror layer, but also to increase the resistance to environment.

As Mirror Ink layer is not strong against the humidity, if there is not a covering layer, moisture may invade into the ink layer and corrode the aluminum metal and color will change.

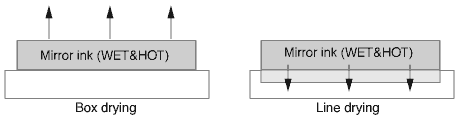

Q3. When drying in a line-dryer, it often gets haze, but why?

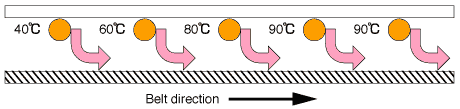

A3. Please set the temperature at the entrance at 40-60 degree C.

Conditions:Printing the Mirror ink onto the PC substrate with cylinder press and dry in a line dryer.

Phenomenon:The Mirror Ink layer gets haze all over and no mirror surface.

Cause:Drying at high temperature from the beginning.

The line-dryer has to be used to dry the printed matter from a cylinder press. As it was impossible to dry at the recommended drying conditions that is 30 minutes at 80 degreeC, 2 minutes at 100 degreeC was applied. We imagine that the solvent in the Mirror Ink was heated up and attacked the PC substrate.

Countermeasure :

1. Lower the dryer temperature lower than 80 degreeC

2. If the line-dryer is long and has several heating zones, temperature of the zones at the entrance should be set at lower temperature and apply the higher temperature (80-100 degreeC) at the following zones. Most of the solvent of the ink evaporates at the first zones and residual solvent will be dried in the following zones to get complete dry, then get excellent mirror finish.

“Patent of Mirror Ink”

Our Mirror Inks are patented and registered as JP 3151606. The patent covers the ink and the printing method with the ink. Printing with a similar ink may infringe the patent.

- Related technology information

- Related event information